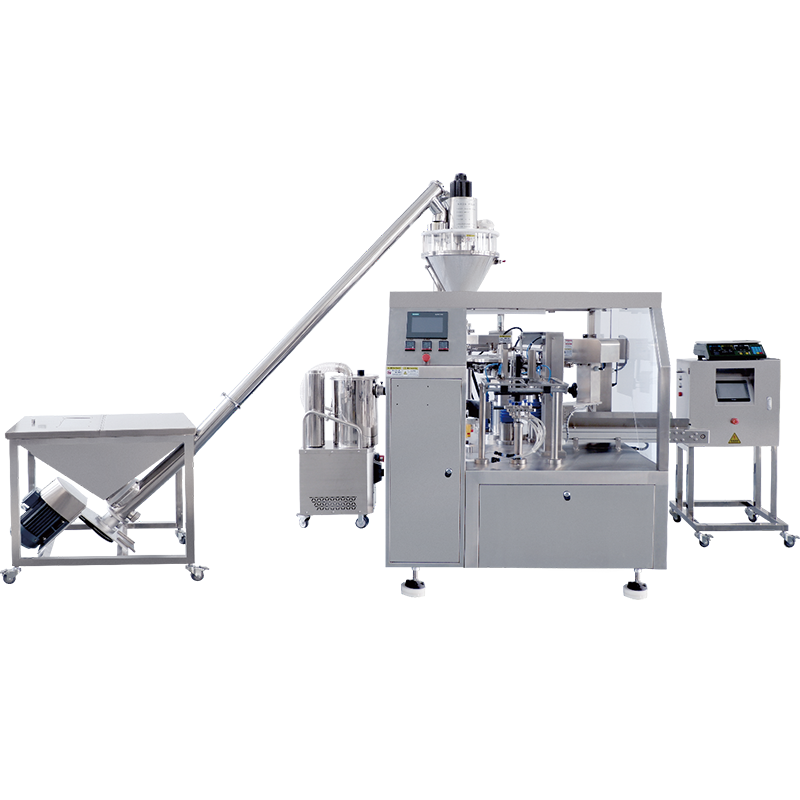

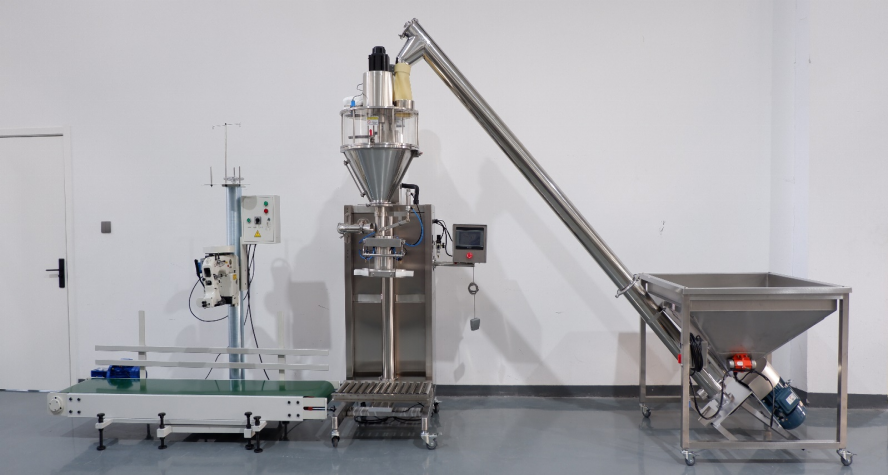

Packing Line Diagram

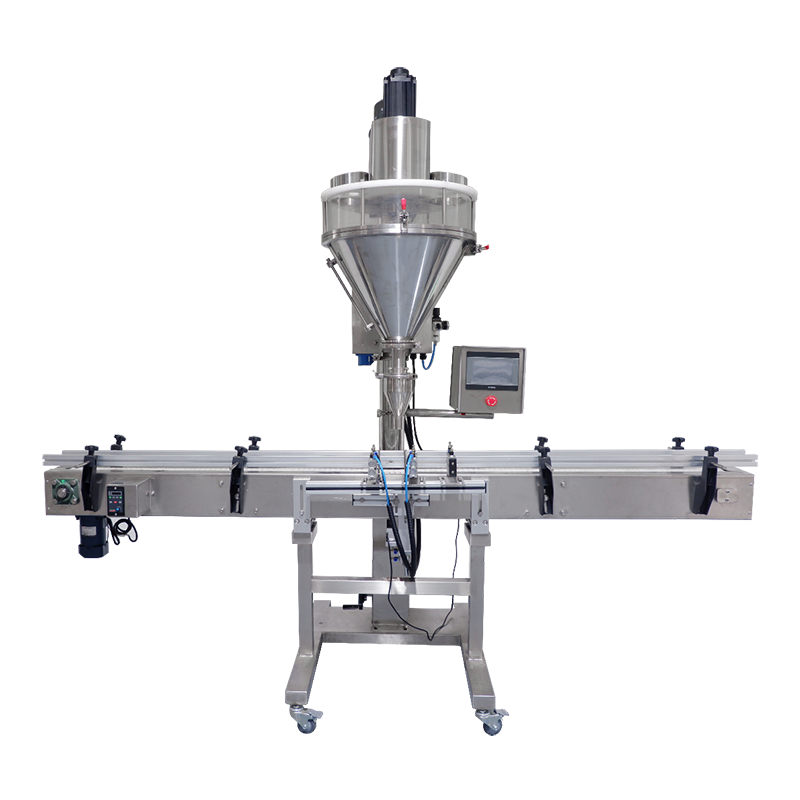

GMB-50R Powder Packing Machine (Weighing)

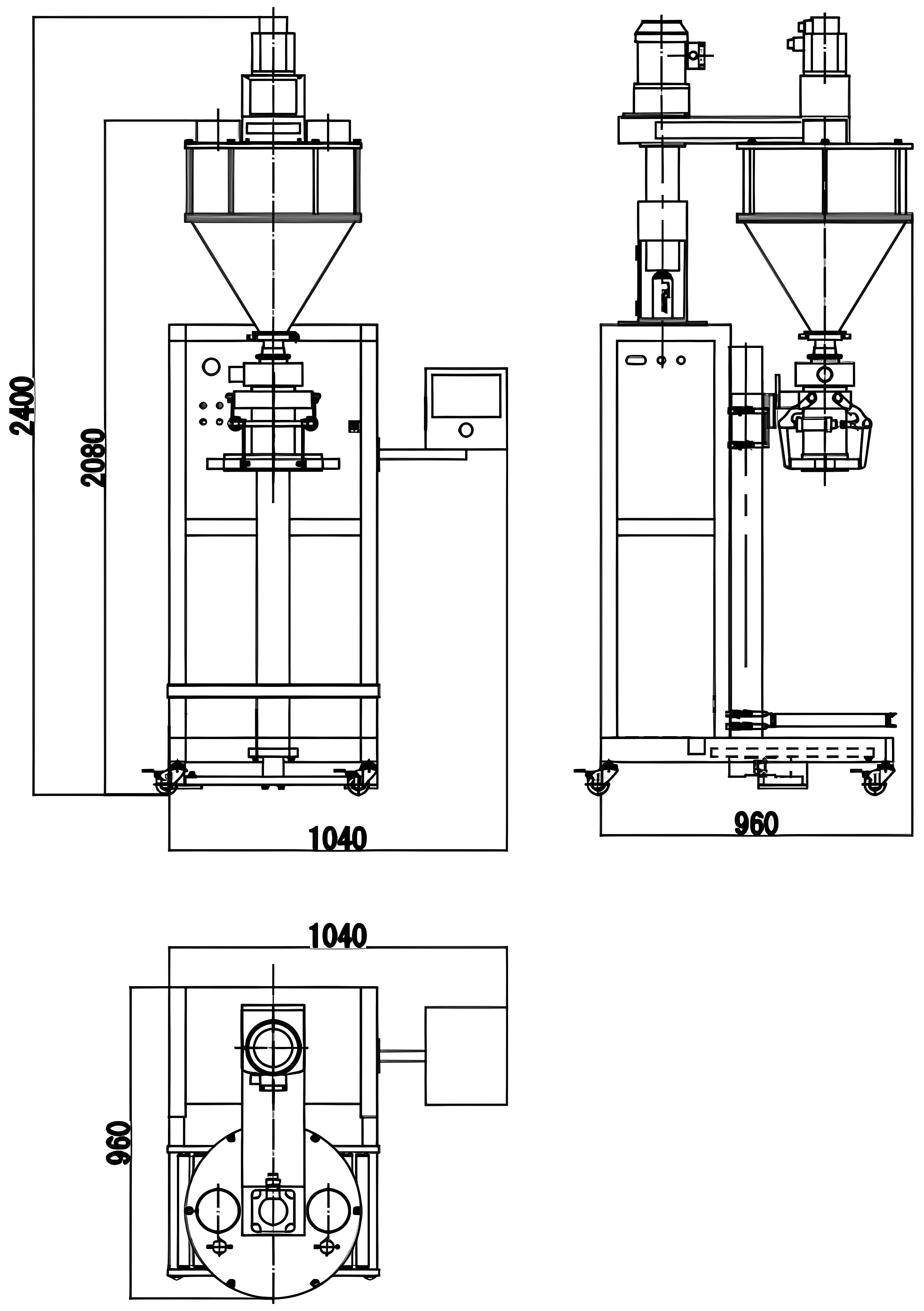

Technical Parameters

Packaging Weight | 5kg-50kg (Depend on materials) |

Accuracy | ≤0.2% (Depend on materials) |

Speed | 60-360 bags/h (Depend on materials) |

Voltage | AC380V AC220V |

Power | 2.7kw |

Weight | 280kg |

Hopper Volume | 70L |

Feeding Height | 2080mm |

Dimension | L 1040×W 960×H 2400mm |

(The above are standard sizes, all parameters can be customized)

Detailed Introduction

Summary:

The machine is suitable for quantitative packaging of powdery, granular and pellet materials. It can be widely used in food, daily chemicals, veterinary drugs, pesticides, fertilizers, feed, additives and other industries.

It can form a production line with a feeder and a sealing machine.

Working Principle:

Weighing measurement: Adjust the set double-level weight parameters of fast and slow (corresponding to the double-level filling speed of fast and slow) to change the speed of the filling screw rotation, thereby adjusting the filling speed and accuracy:

(1) Fast filling, then start slow filling after reaching the "fast weight"

(2) Slow filling, stop filling after reaching the "slow weight"

Advantages and Characteristics

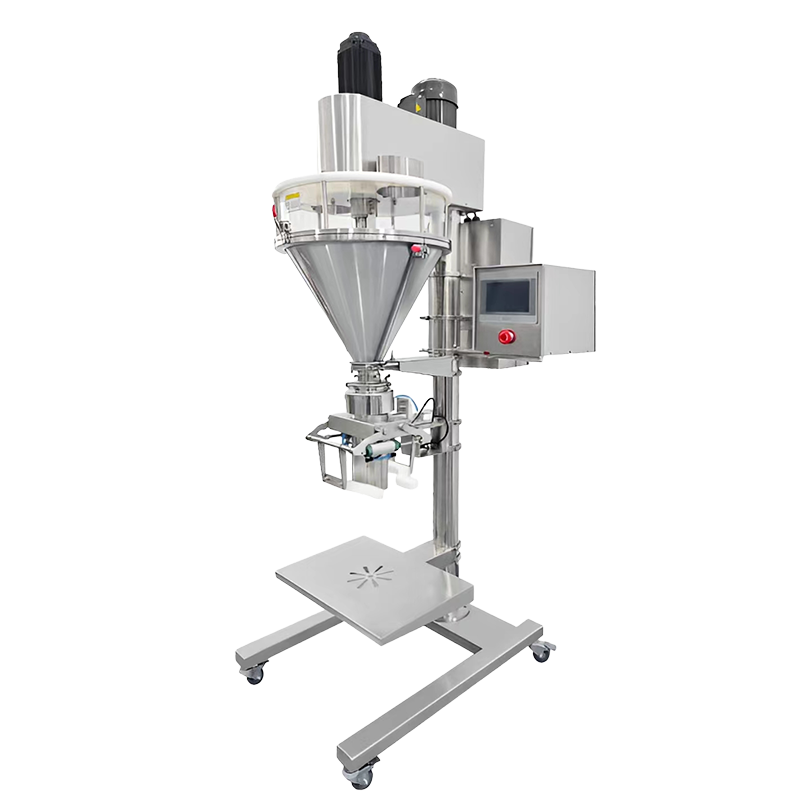

1. Accurate packaging: Adopting industrial-grade weighing module and PLC control system, weighing is stable and accurate.

2. Easy to clean: The hopper can be fully opened, which is easy to clean.

3. Convenient installation: Full quick-release clamp connection, simple installation.

4. Stable filling: The filling system is equipped with a time function, and the material level switch can also be fed normally when it fails; the material level switch can be installed not only in the hopper, but also on the outside to prevent the switch from failing.

5. Transparent silo: The material operation status is clear at a glance.

6. Stable structure: high-precision processing, perfect mechanical structure, highly concentric components (motor, long shaft, silo, screw, material cup, etc.), high machine operation efficiency, less wear, greatly reducing the failure rate of screw non-concentricity.

7. No leakage: There is a synchronous stirring function, which can solve a large part of the leakage problem of dry, loose and fine materials.

8. Easy maintenance and repair: The hopper can be fully opened, and the internal components of the hopper are clearly visible:

a) Convenient to adjust the relative position between the agitator and the filling screw

b) Convenient to maintain and repair each component (agitator, metering screw, long shaft, etc.).

9. Simple operation: Equipped with an electronic touch screen, parameters can be set directly

10. Easy to move: equipped with universal wheels.

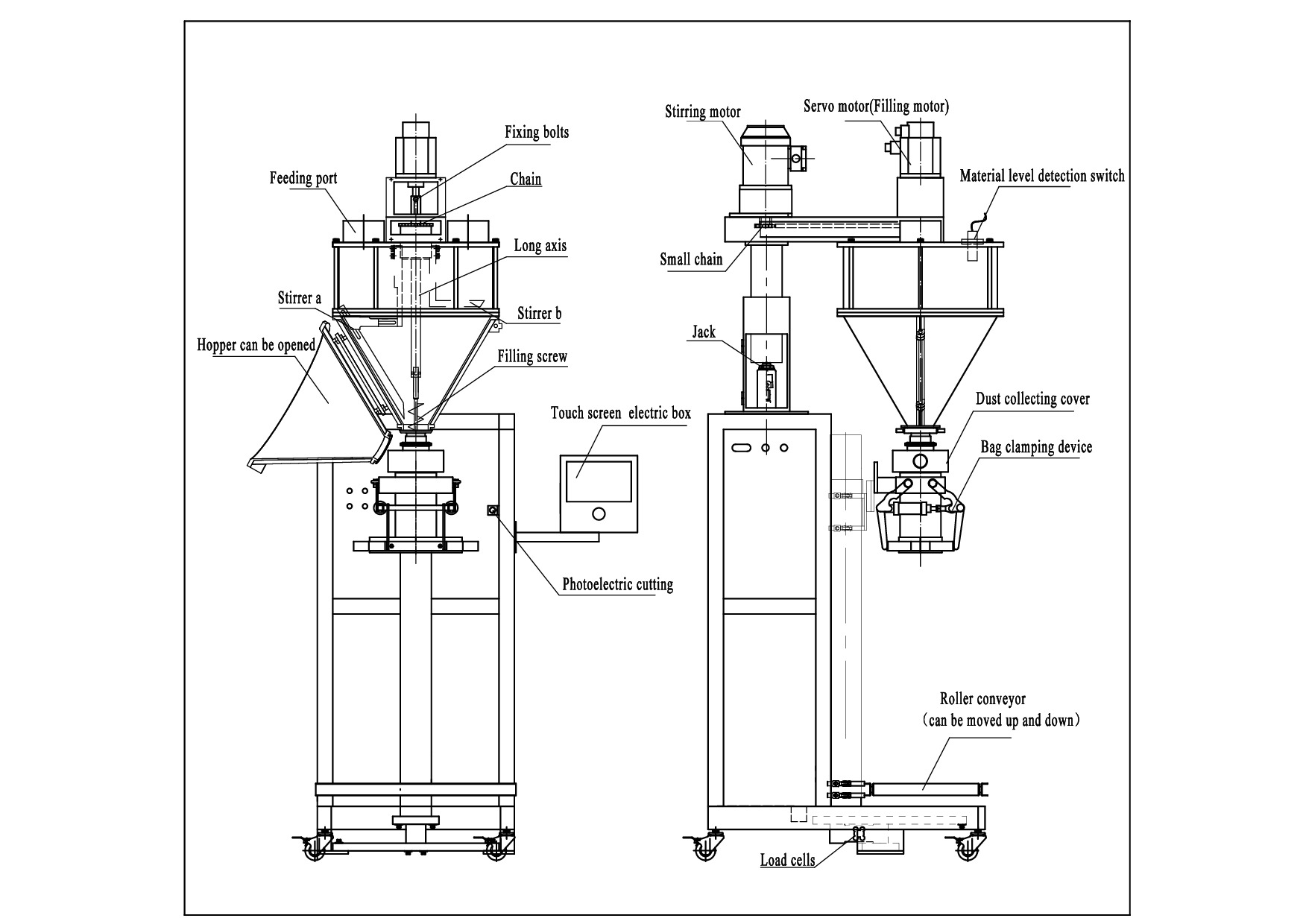

Structure Diagram

Dimension Diagram

Additional Accessories

Notes:

1. Two electric boxes: The strong and weak electricity are separate.

2. Roller conveyor can be moved up and down to adapt different sizes of bags.

3. Dust collecting cover can be connected with a dust cleaner.

4. Adjusting the height with a jack.

5. There is a stirrer in the hopper to help with filling.

6. There is a emergency stop switch.

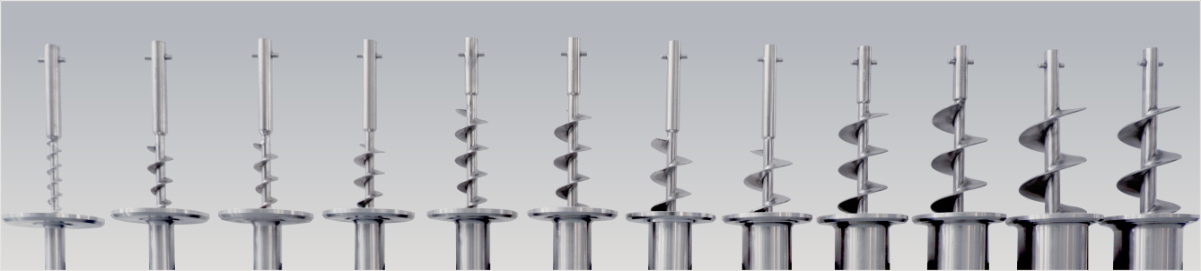

Additional Accessories (Different requirements)

Screw Outer Diameter(mm) | Cup Outer Diameter(mm) | Prevent leakage Outer Diameter(mm) | Packing Size | Bag clamping device Outer Diameter(mm) |

Φ60 | Φ65 | 67 | 1kg-5kg | Φ89 |

Φ64 | Φ69 | 71 | 3kg-5kg | Φ89 |

Φ70 | Φ75 | 77 | 5kg-50kg | Φ89 |

Φ89 | Φ94 | 96 | 5kg-50kg | Φ133 |

|

|

Leakage Prevention Device | Pressure Plate |

|

|

Stop Valve | Cylinder |

|

|

Dust Collecting Cover | Centrifugal Leakage Prevention Device |

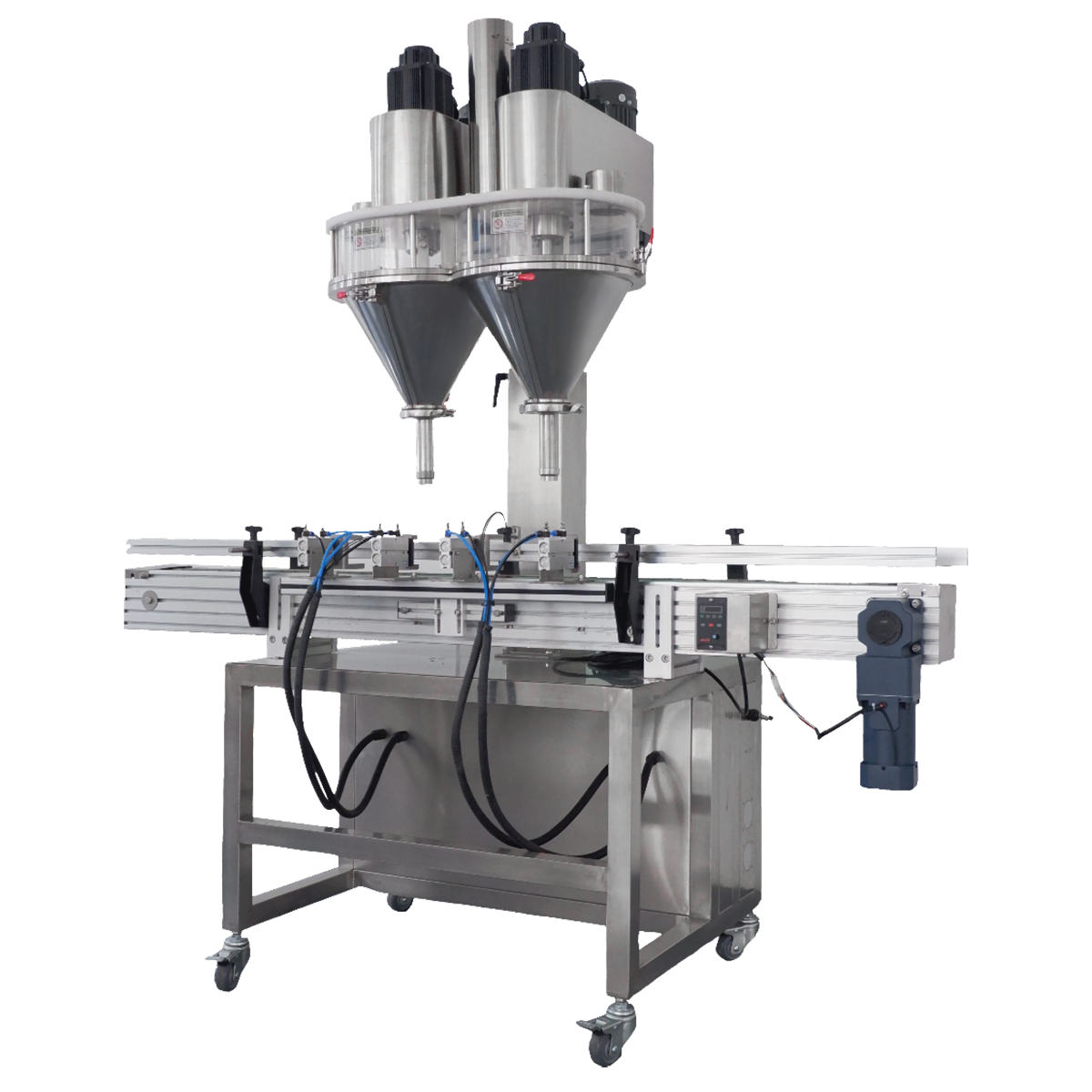

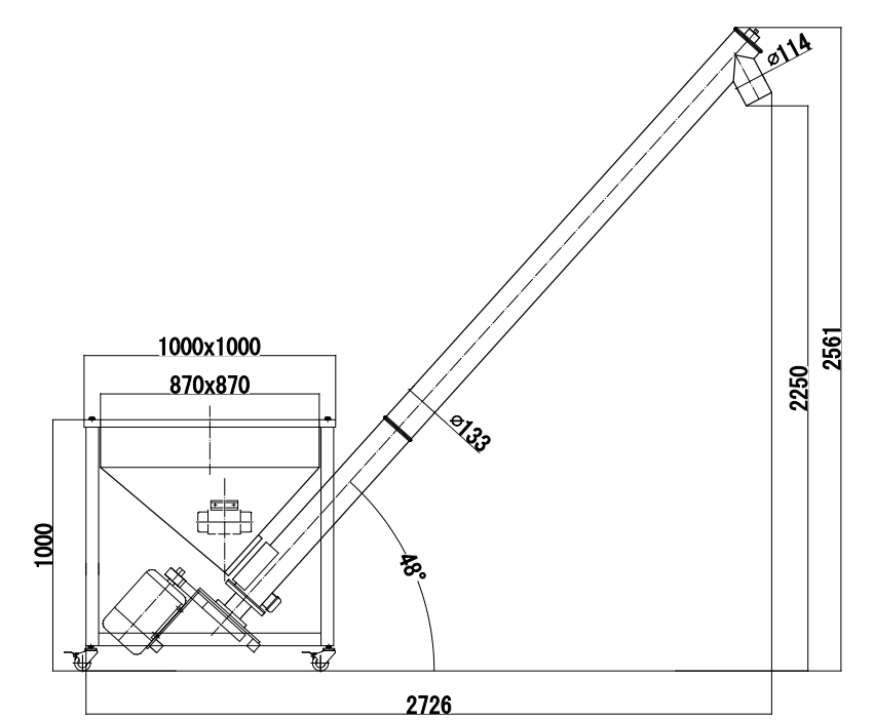

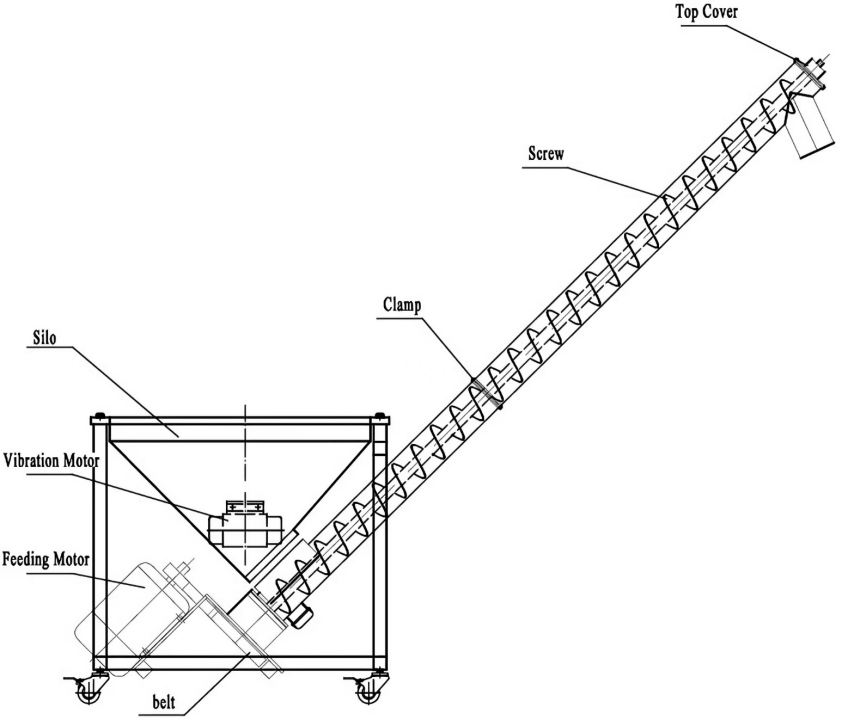

Screw Feeding Machine

Features:

1. Belt power: The power is connected by a motor and belt, which has high conveying speed.

2. Adjustable transport capacity: The feeding port is equipped with an adjustable gate to control the flow of feeding.

3. Prevent material bridging: The silo wall is equipped with a vibration motor.

4. Convenient cleaning: There is a forward and reversal switch. Turn on the reversal switch to clean and forward switch to feed.

5. Convenient disassembly and installation: Full quick-install connection, no tools are required to thoroughly clean the residual material; silicone connection between the silo and the material tube; the barrel can be disassembled into two sections.

6. No powder jamming: The bearing adopts a unique sealing method, no powder is fed in, and no overflow is allowed.

7. Automatic work: It can be automatically controlled by the matching filling machine without manual intervention.

8. Good quality: Corrosion-resistant, auger blades are 3mm thick and not easy to deform.

9. Movable: Install universal wheels with brakes, easy to move, no noise.

Technical Parameters:

Feeding Pipe | 133mm |

Transport Capacity | 3000-5000kg/h (depends on material) |

Silo Volume | 300L |

Voltage | AC380V |

Power | 2.2kw |

Weight | 180kg |

Feeding Height | 2250mm |

Silo Height | 1000mm |

Dimension | L2730×W1000×H2500mm |

(The above are standard sizes, all parameters can be customized)

Dimension Diagram:

Structure Diagram:

Main Configuration:

No. | Name | Brand | Origin |

1 | Feeding Motor | YUTONG | China Henan |

2 | Vibration Motor | ANBO | China Zhejiang |

3 | Forward and Reversal Switch | JINGYI | China Shanghai |

4 | Bear | LUOZHOU | China Henan |

Random Accessories:

No. | Name | Quantity |

1 | Clamp | 2 |

2 | Gasket | 2 |

3 | Soft Connection | 1 |

Dust Cleaner

Features:

1. Adopt 304 stainless steel silo.

2. Adopt HEPA high precision filter, the filter is multi-layer.

3. It has protection function to prevent from electricity leakage, phase loss and overload.

4. Equipped with a pressure relief device, it can automatically relieve pressure in the case of high negative pressure (some models).

5. Adopt upper and lower separation barrels for easy loading and unloading.

6. Equipped with silent casters, it is light and fast.

Technical Parameters:

Air Flow | 280m³/h |

Main Filter Area | 15000cm³ |

Power | 1.75kw |

Vacuum | 21kpa |

Voltage | AC380V AC220V |

Inner Diameter | 40mm |

Noise | 64DB/A |

Weight | 75kg |

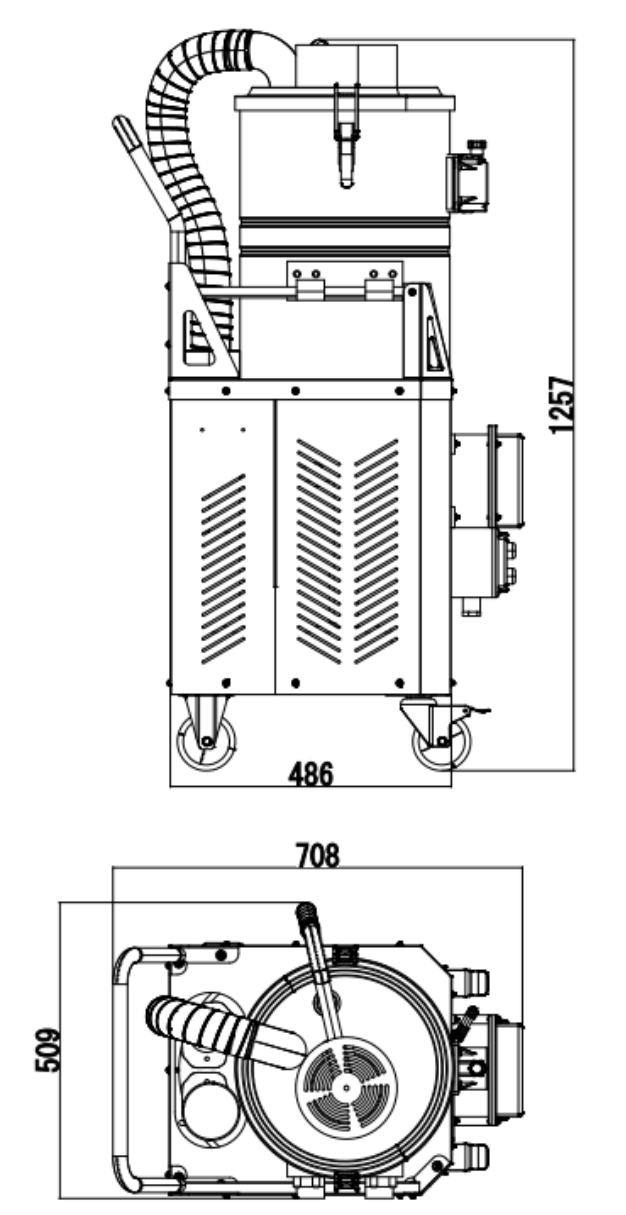

Dimension Diagram:

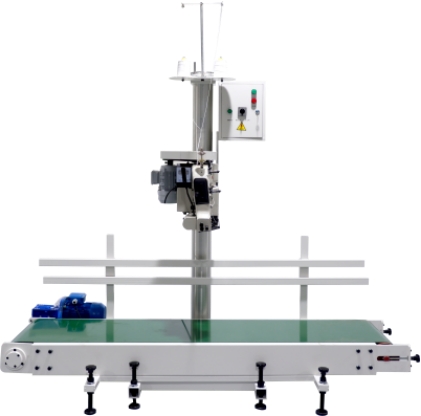

Sewing Machine

Features:

1. It is consisting of belt conveyor, sewing machine, folding structure, post and electric control system.

2. Set automatic boot, stop, and other functions in one, with good performance, long service life and other characteristics.

3. Suitable for high-speed conveying sewing bag, flour bag, jute bag, plastic woven bag and others.

4. Suitable for grain, chemical industry, port, fertilizer, feed and other industries of particles, powder bulk material.

Technical Parameters:

Speed | 7-12 m/min |

Sewing Bag Height | 400-900mm |

Belt Height from Ground | 260mm(can up +100mm) |

Belt Width | 450mm |

Belt Length | 2000mm |

Sewing Bag Weight | ≤50kg |

Voltage | AC380V AC220V |

Power | 1.2kw |

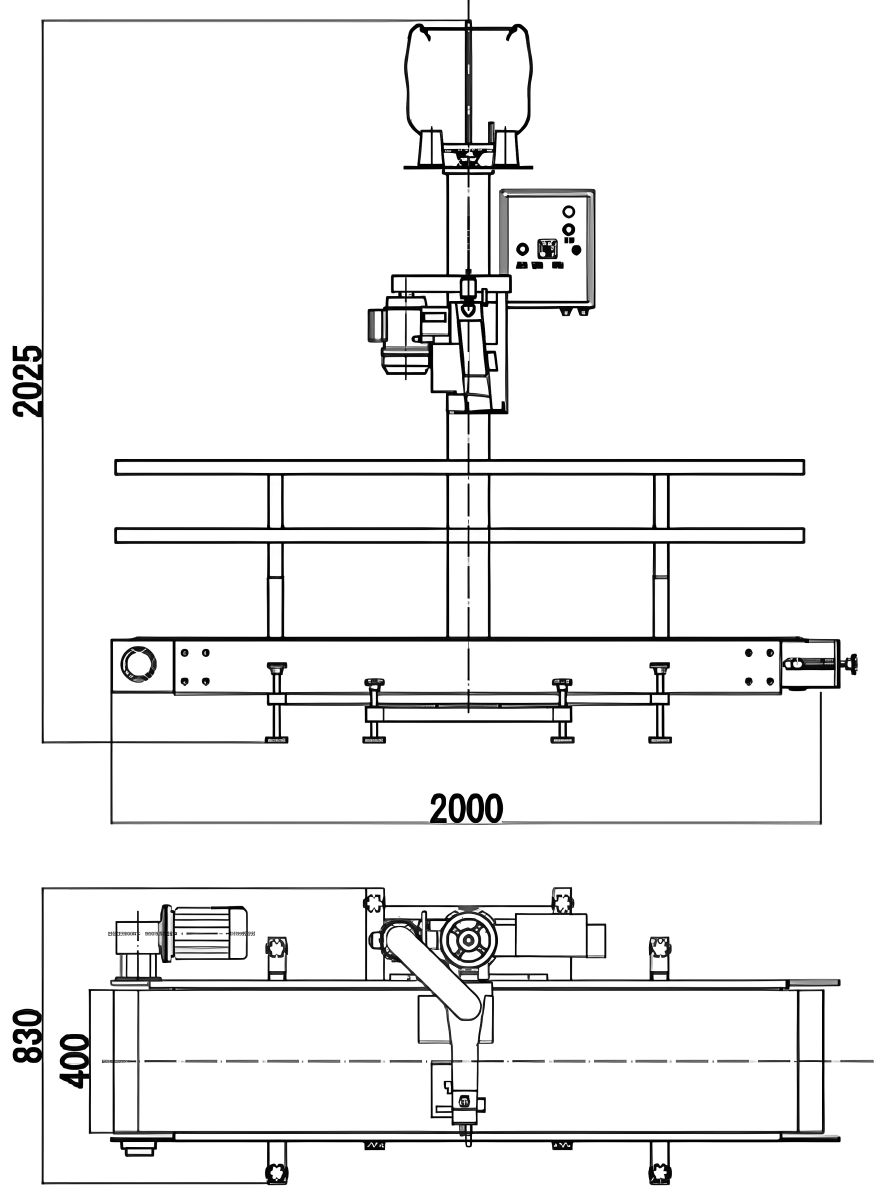

Dimension | L 2000×W 830×H2025mm |

Dimension Diagram:

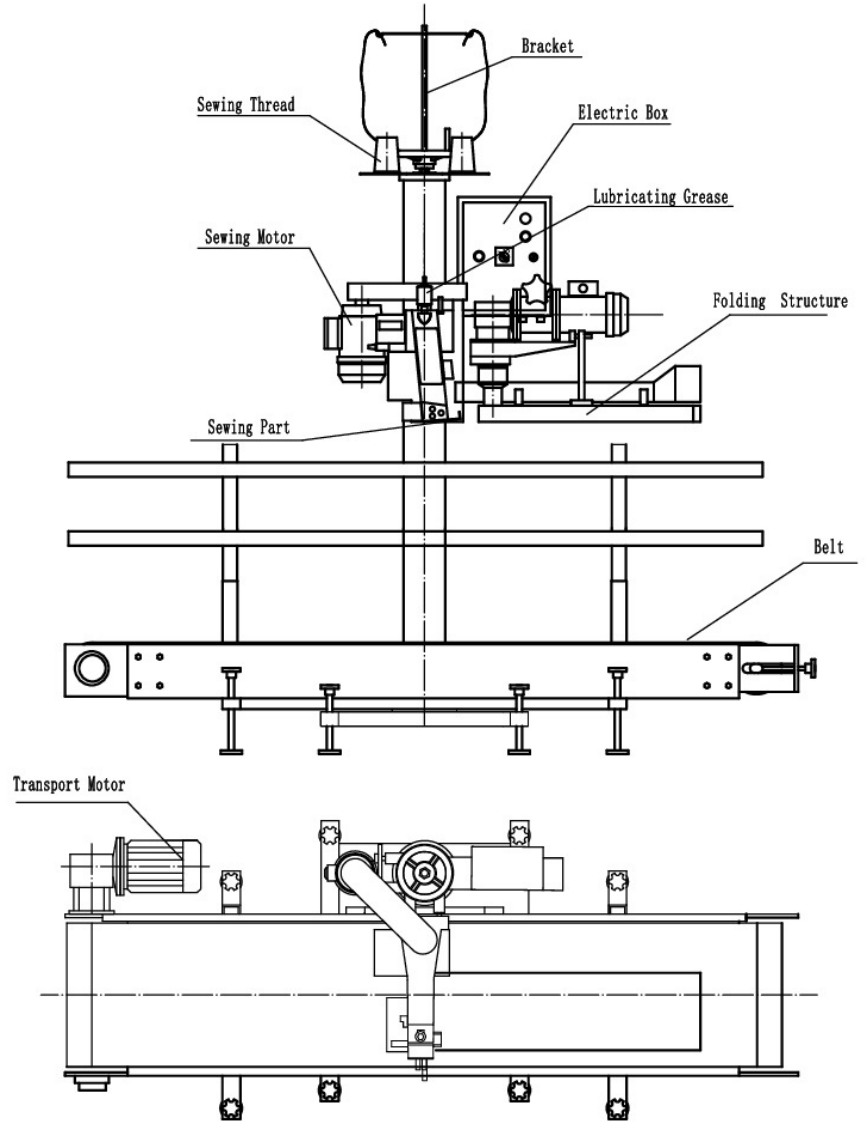

Structure Drawing:

QF-600LD Plastic Sealing Machine

Characteristics

1. The machine uses compressed air as the power, sealing pressure is adjustable, stable and reliable quality, dual heating model, suitable for hot sealing thick packaging bags.

2. New baking paint process, smooth and bright, enduring, easy to clean.

3. Manual or foot moving double operation is simple and easy, flexible operation mode.

4. Double heating function, suitable for thicker packaging bags.

Parameters:

Power | 800W | ||

Sealing Width | 10mm | ||

Film thickness | ≤0.18mm | ||

Sealing Length | 600mm | 800mm (customized) | 1000mm (customized) |

Bag Height | 200-750mm | ||

Center to Ground | 900-1400mm | ||

Air Pressure | 0.5MPA | ||

Net Weight | 84kg | ||

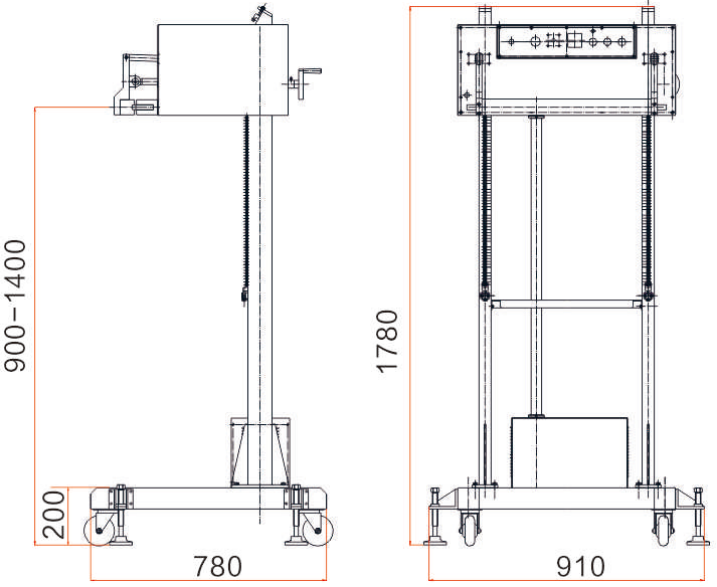

Dimension | 910*780*1780mm | ||

Diagram:

QF-600L/S Pneumatic plastic sealing machine

Characteristics

1. New baking paint process, smooth and bright, enduring, easy to clean.

2. High-quality stainless steel conveyor table, smooth surface, durable and wear-resistant, can be connected to the conveyor table.

3. Manual or foot moving double operation is simple and easy, flexible operation mode.

4. Simple and easy to operate, and flexible in the operation mode.

Technical parameter

Power | 800W | |

Sealing width | 8-10mm | |

Film thickness (single layer) | ≤0.18mm | |

Sealing length | 600mm | 800mm (customized) |

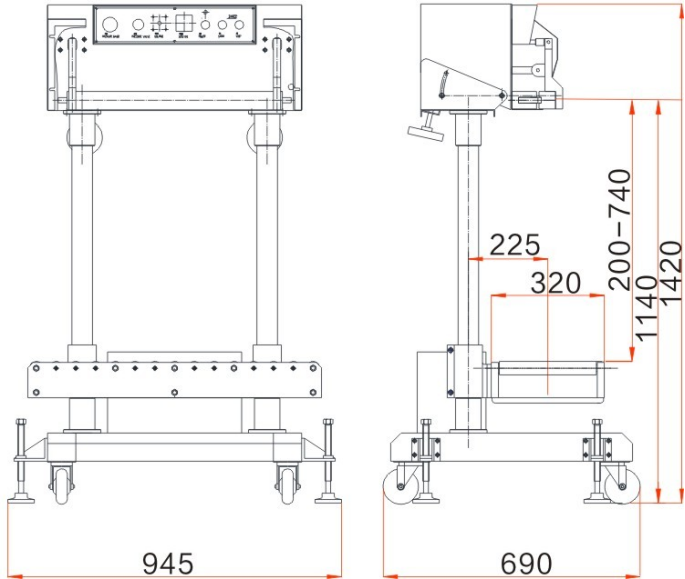

Bag height | 200-750mm | |

Max sealing load | 50kg | |

Center of seal to ground height | 1140mm | |

Gas source air pressure | 0.5mpa | |

Weight | 80kg | |

Dimension | 945*725*1420mm | |

Dimension drawing