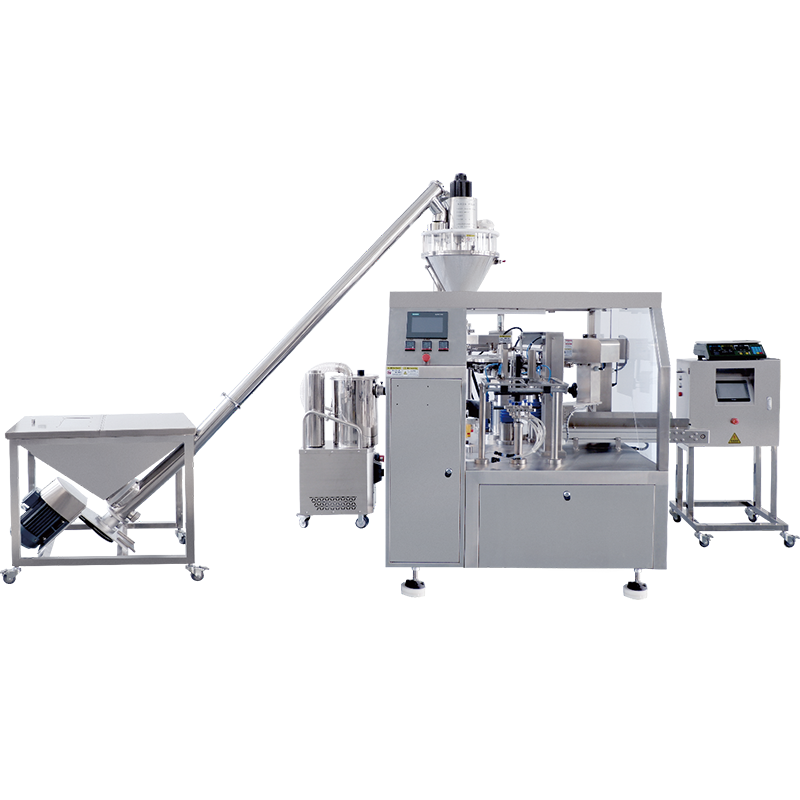

Roll Film Bag Packing Machine

Performance characteristics:

1. Automatically complete measuring, bag making, filling, sealing, cutting, coding and other work.

2. Servo motor film drawing, accurate positioning; Double belt film pulling, fast speed.

3. Gas path control and circuit control are independent of each other, and the noise is small.

4. Equipped with dual axis PLC, strong anti-interference.

5. External piercing mechanism, easy to install.

6. Adjusting the deviation of the bag only needs to be operated on the color touch screen, which is simple and convenient.

7. The whole machine adopts a closed mechanism to block dust.

Main Components:

No. | Name | Brand | Origin |

1 | PLC | Schneider | German |

2 | Touch Screen | Schneider | German |

3 | Servo Motor | Schneider | German |

5 | Cylinder | AirTAC | Taiwan |

6 | Solenoid Valve | AirTAC | Taiwan |

7 | Triad | AirTAC | Taiwan |

8 | Photoelectric Sensor | AUTONICS | Korea |

9 | Power Switch | MEAN WELL | Taiwan |

10 | Solid Relay | FOTEK | Taiwan |

11 | Intermediate Relay | Omron | Japan |

12 | Temperature Control | AISET | China |

13 | Level Sensor | LEIKE | China |

14 | Switch | Schneider | German |

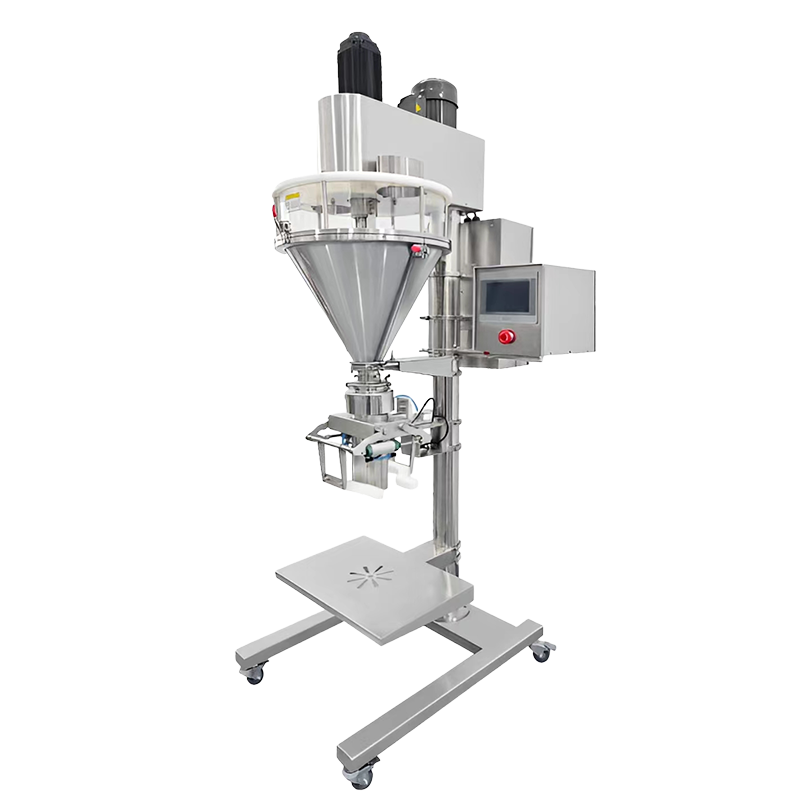

Auto Packing Machine (Roll Film)

Technical Parameters

Packing Accuracy | ≤1% (Depends on materials and packing size) |

Power | 1.5kw |

Machine Weight | 80kg |

Dimension | L 780×W 880×H 1900mm |

(These are standard above, all parameters can be customized)

Detailed Introduction

Working Principle:

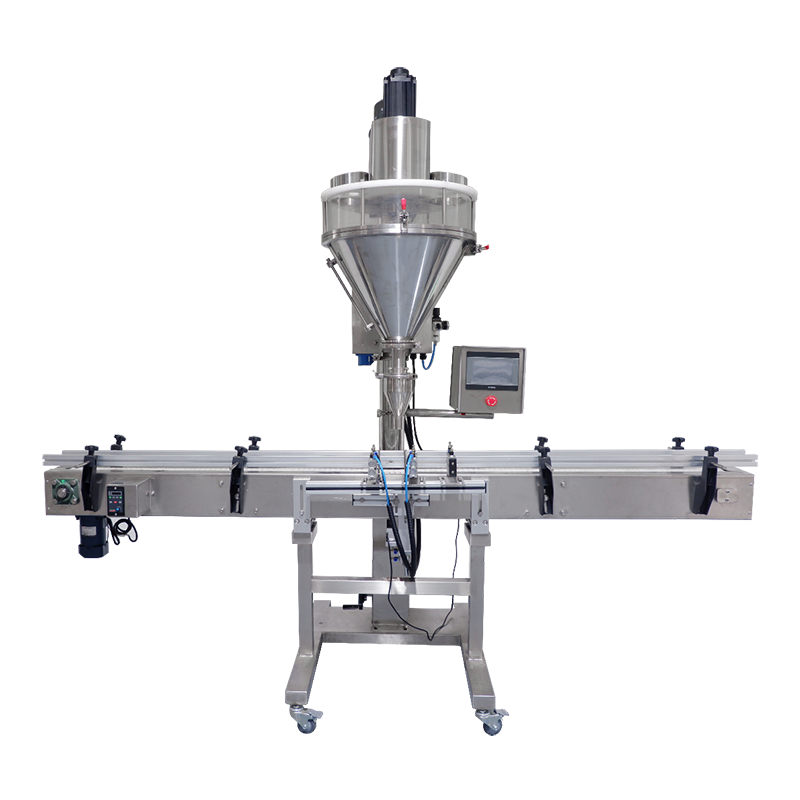

Volume measurement: adjust the pulse value to change the number of revolutions of the filling screw, thereby changing the filling weight (the larger the pulse, the more material is fed). When filling, use an electronic scale to feedback the weight, and the system will automatically adjust the pulse value.

Advantages and Characteristics

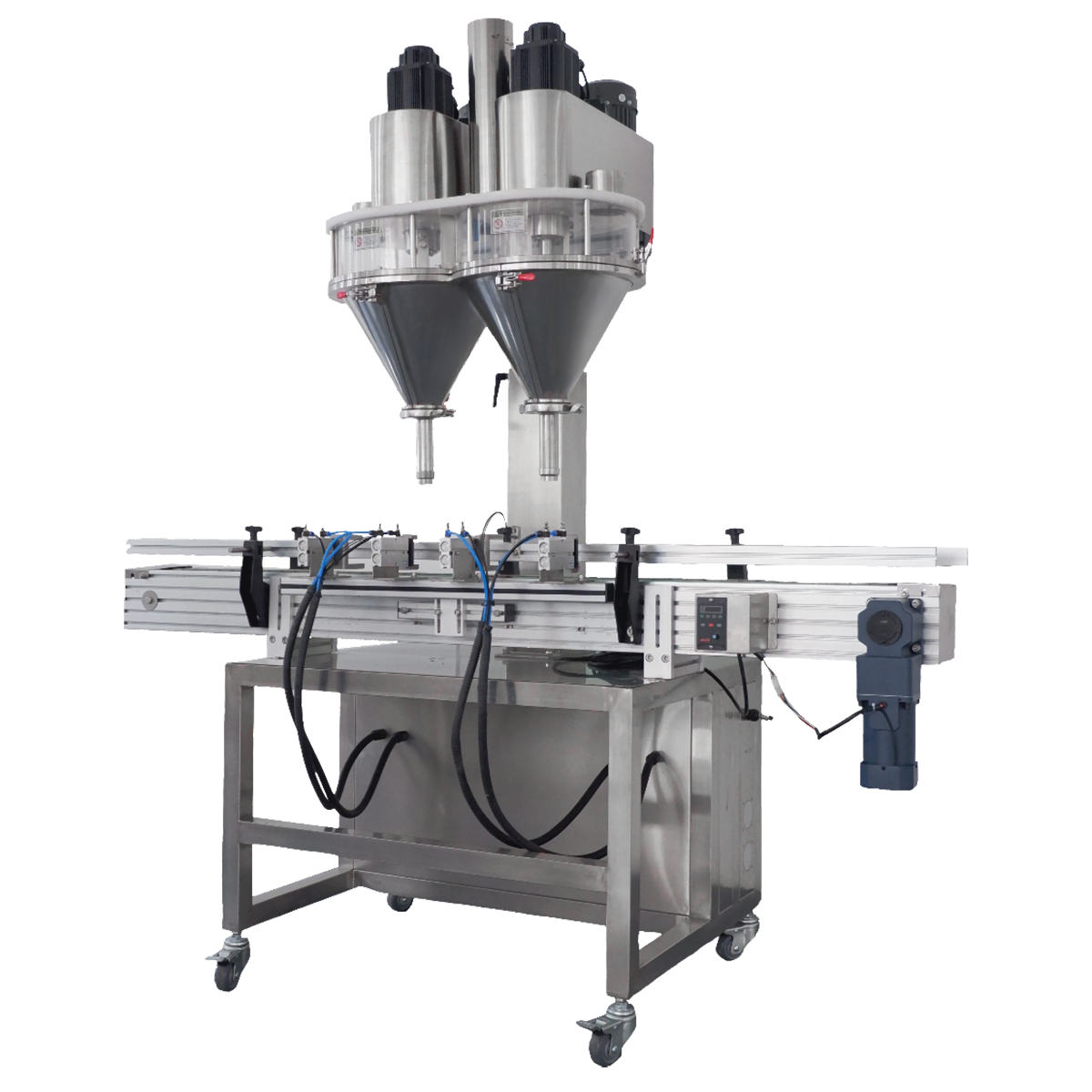

1. Accurate packaging: Adopting high quality screw, stable and accurate.

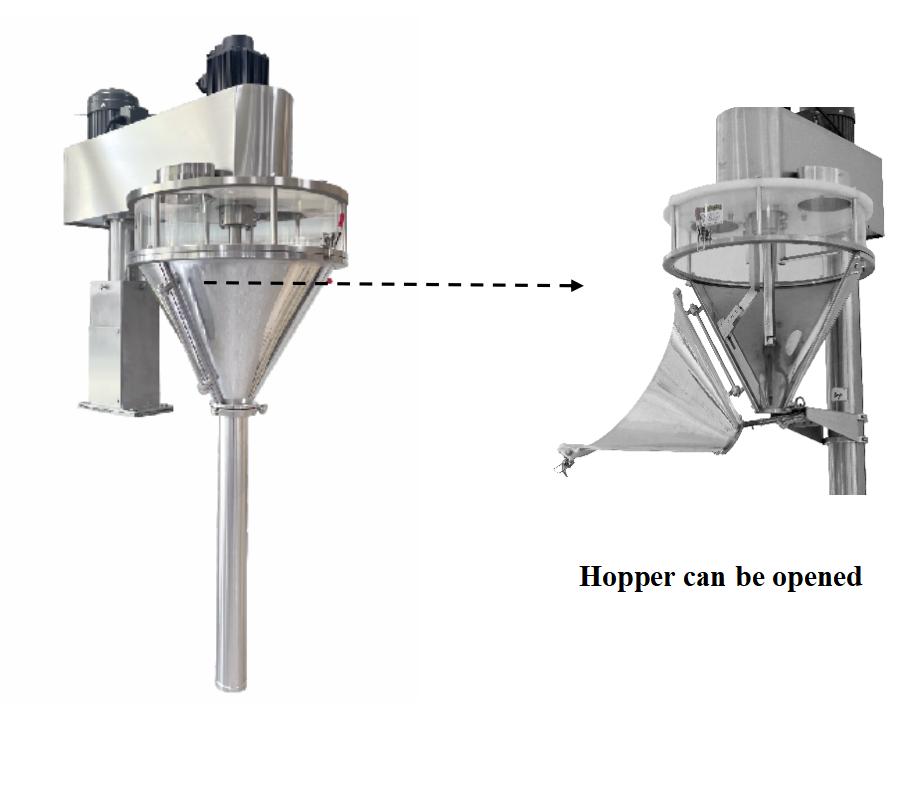

2. Easy to clean: The hopper can be fully opened, which is easy to clean.

3. Convenient installation: Full quick-release clamp connection.

4. Transparent silo: The material operation status is clear at a glance.

5. Stable structure: high-precision processing, perfect mechanical structure, highly concentric components (motor, long shaft, silo, screw, material cup, etc.), high machine operation efficiency, less wear, greatly reducing the failure rate of screw non-concentricity.

6. No leakage: There is a synchronous stirring function, which can solve a large part of the leakage problem of dry, loose and fine materials.

7. Easy maintenance and repair: The silo can be fully opened, and the internal components of the silo are clearly visible:

a) Convenient to adjust the relative position between agitator and screw.

b) Convenient to maintain and repair each component.

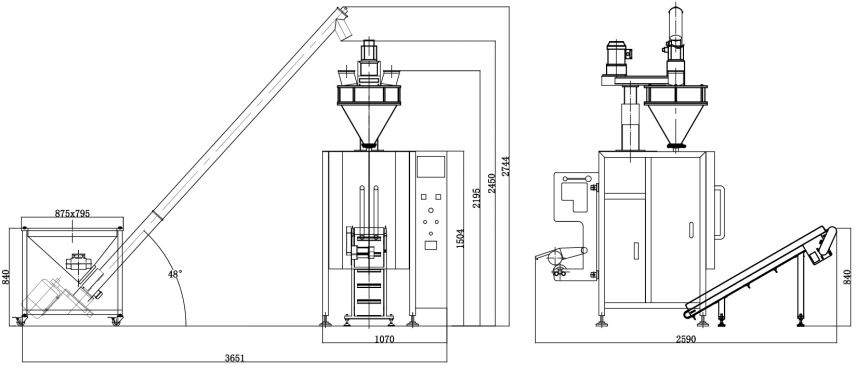

Structure Diagram

Dimension Diagram

Additional Accessories

Screw Conveyor (APT-T2)

Features:

1. Adjustable transport capacity: The feeding port is equipped with an adjustable gate to control the flow of feeding.

2. Prevent material bridging: The silo wall is equipped with a vibration motor.

3. Convenient cleaning: There is a forward and reversal switch. Turn on the reversal switch to clean and forward switch to feed.

4. Convenient disassembly and installation: Full quick-install connection, no tools are required to thoroughly clean the residual material; silicone connection between the silo and the material tube; the barrel can be disassembled into two sections.

5. Automatic work: It can be automatically controlled by the matching filling machine without manual intervention.

6. Good quality: Corrosion-resistant, auger blades are 3mm thick and not easy to deform.

7. Movable: Install universal wheels with brakes, easy to move, no noise.

Technical Parameters:

Feeding Pipe | 108mm |

Transport Capacity | 1000-3000kg/h (depends on material) |

Silo Volume | 120L |

Power | 2.5kw |

Voltage | AC380V |

Weight | 300kg |

Feeding Height | 2450mm |

(The above are standard sizes, all parameters can be customized)

Conveyor