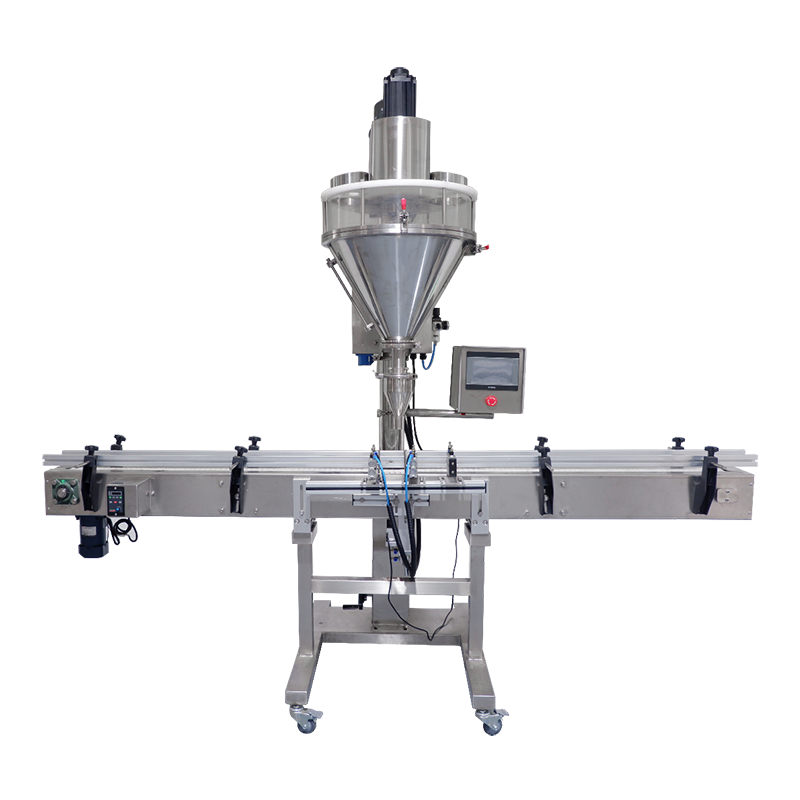

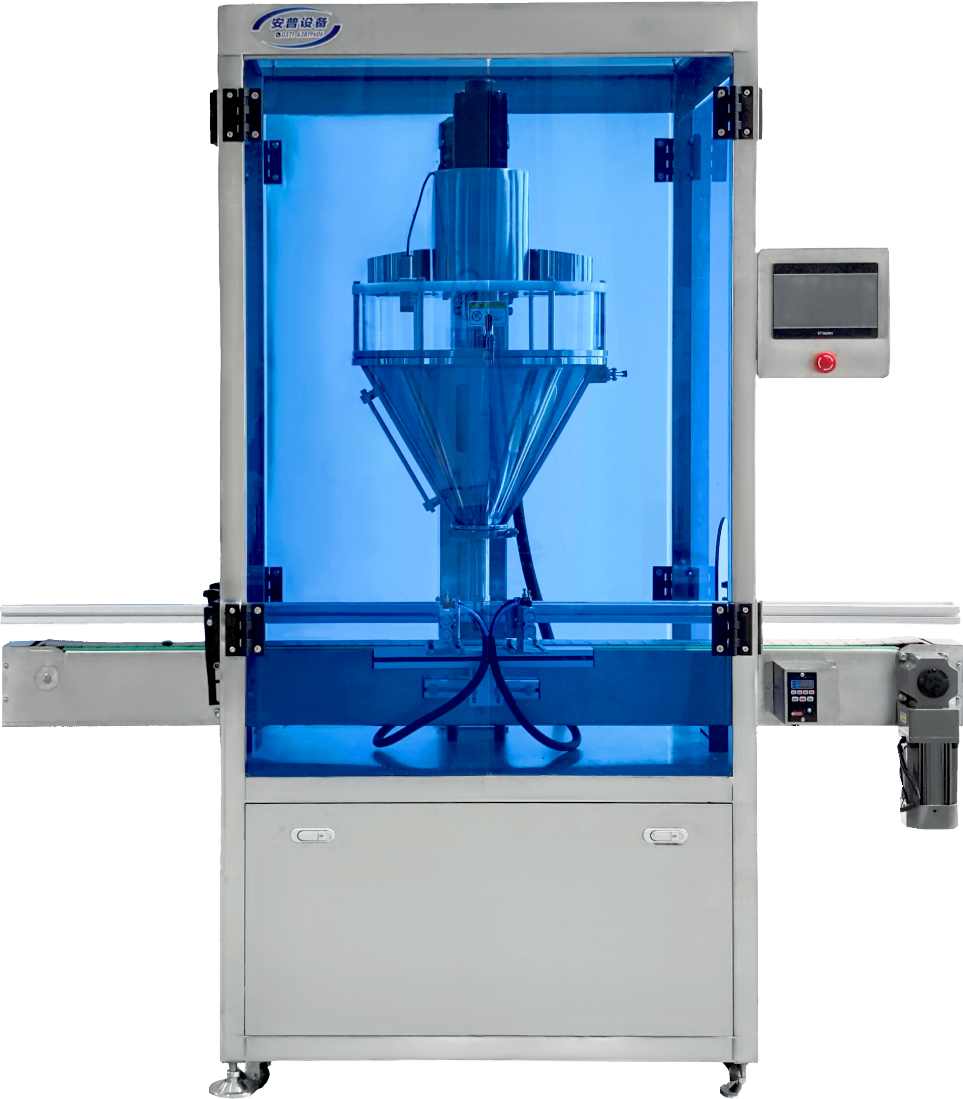

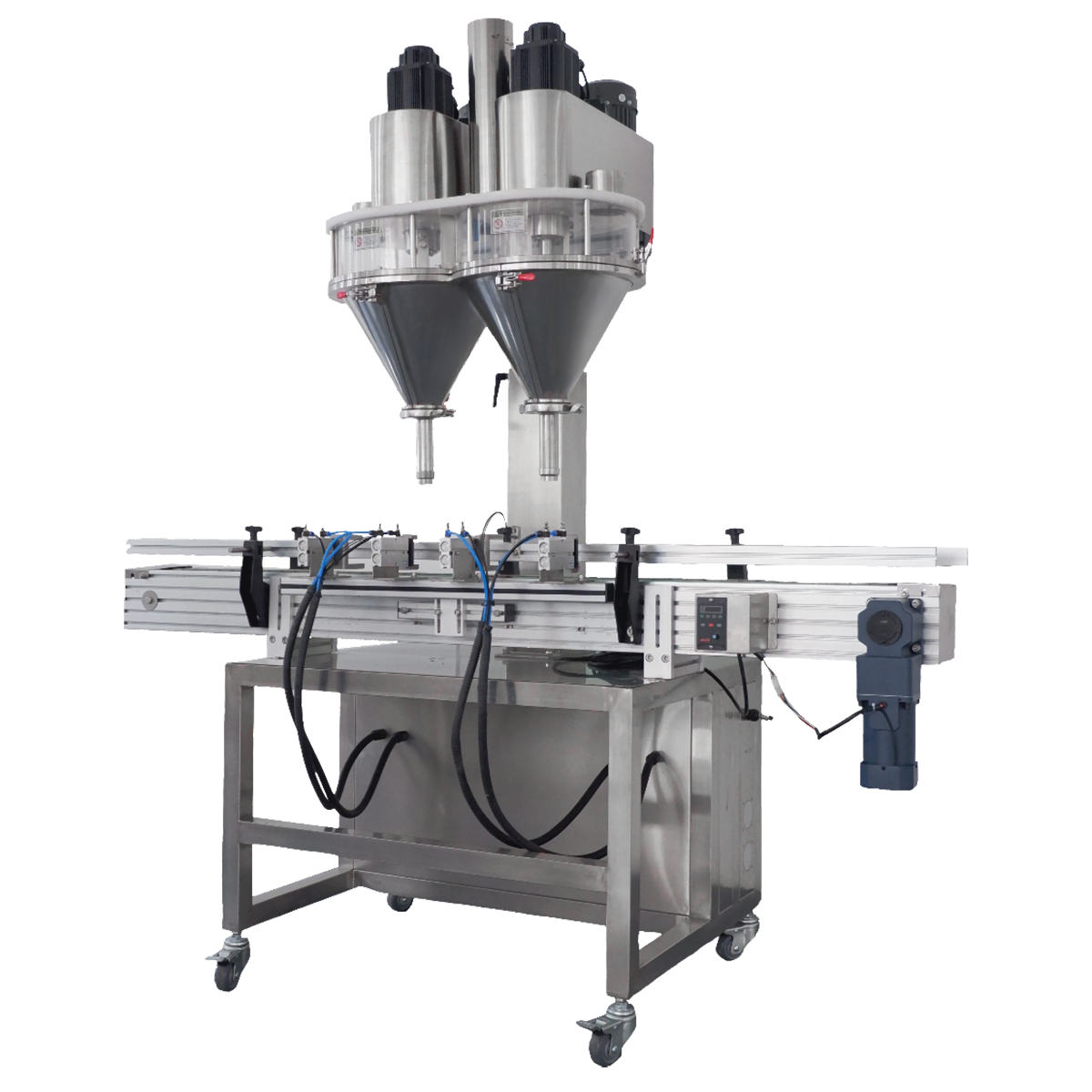

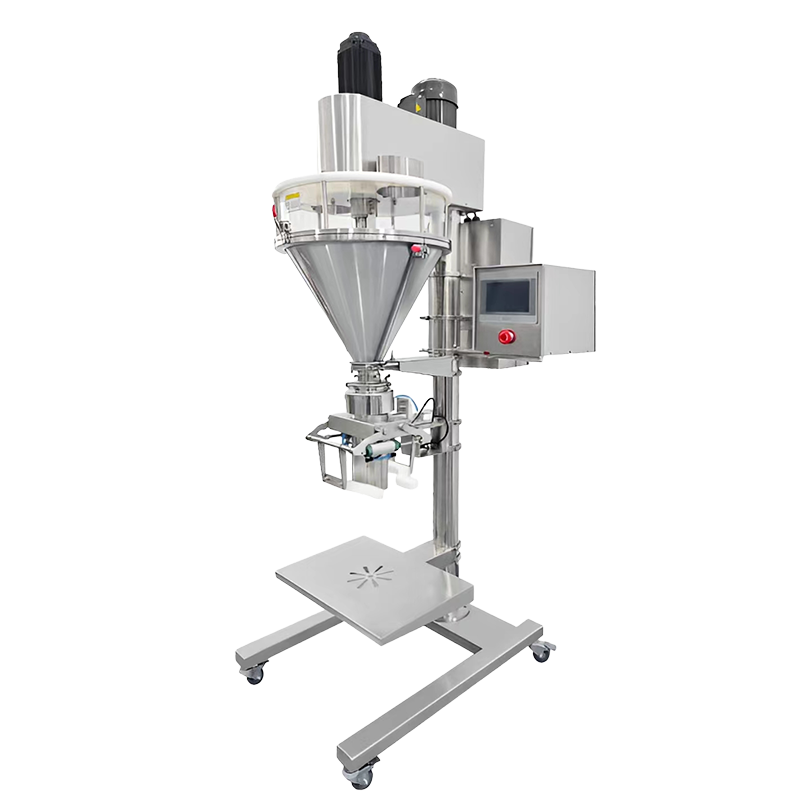

APG-01B Single Head Powder Filling Mchine

Technical Parameters

Measuring | Volume | Weight |

Packing Weight | 10g-1000g (Depend on materials) | 10g-5000g (Depend on materials) |

Packing Speed | 20-40(bottles/min) | 5-25(bottles/min) |

Packing Accuracy | ≤1% | ≤0.3% |

Power | 2kw | |

Detailed Introduction

Advantages and Characteristics

1、 Automatic positioning, filling and metering of bottles can be realized.

2、 Vibration device can be added to conveyor belt to ensure uniform filling .

3、 The hopper can be fully opened, convenient to disassemble and clean.

4、 The servo motor is used to drive the screw, which is not easy to wear, accurate positioning, adjustable speed, stable performance, etc.

5、 PLC control system is adopted, which has the advantages of stable operation, anti-interference, and high weighing accuracy.

6、 All 304 stainless steels, all quick clamp connections, easy installation.

7、 The touch screen clearly displays each working status, operation instructions, fault status and production statistics, etc., and the operation is simple and intuitive.

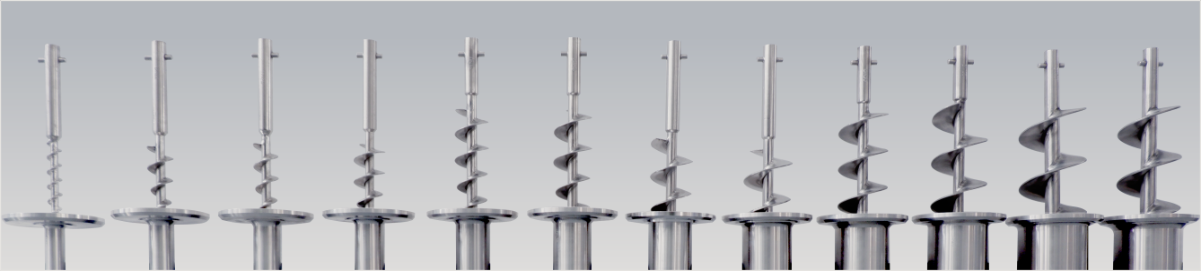

8、 The screw accessories can be replaced, which can be used for a variety of materials from ultra-fine powder to small particles.

9、 High-precision processing, perfect mechanical structure, high concentricity of each component, high operating efficiency, and less wear.

10、 The silo can be fully opened, and the status of the internal components of the silo is clear at a glance:

1) Convenient to adjust the position between the agitator and screw.

2) Convenient maintenance and inspection of various components.

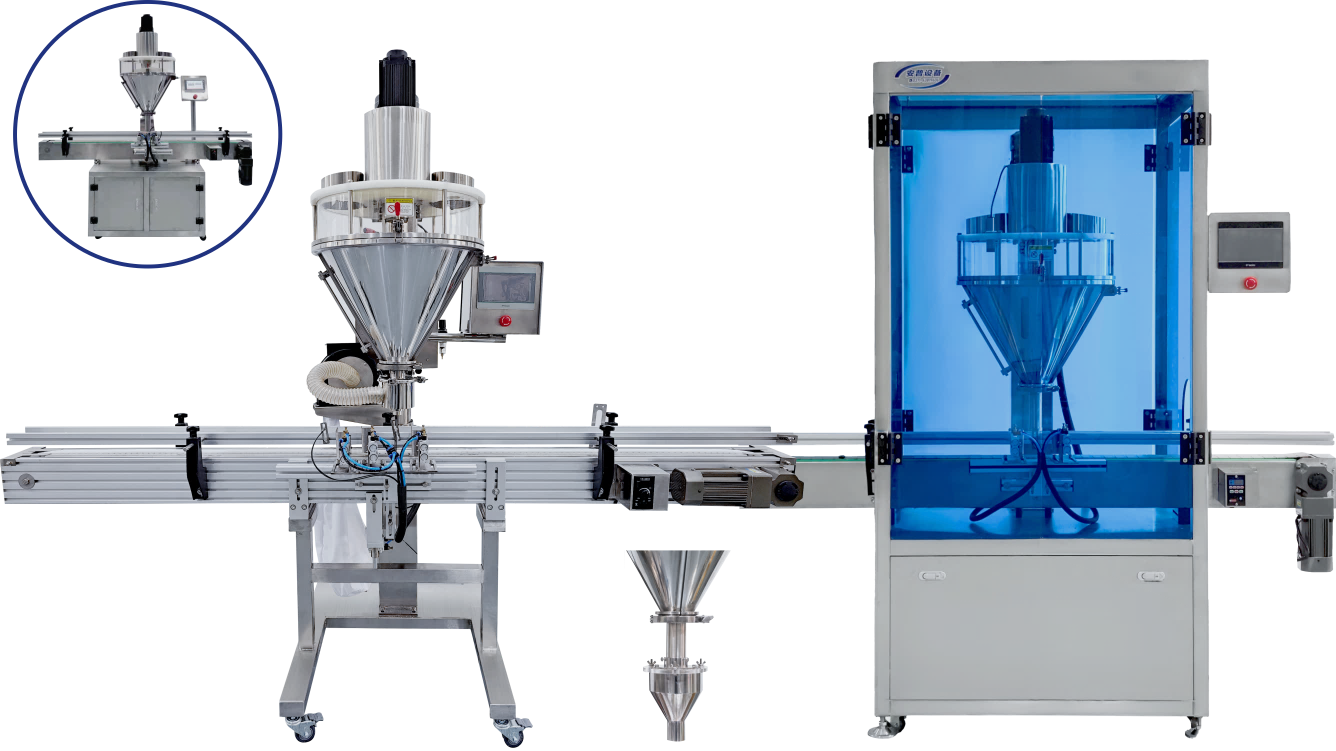

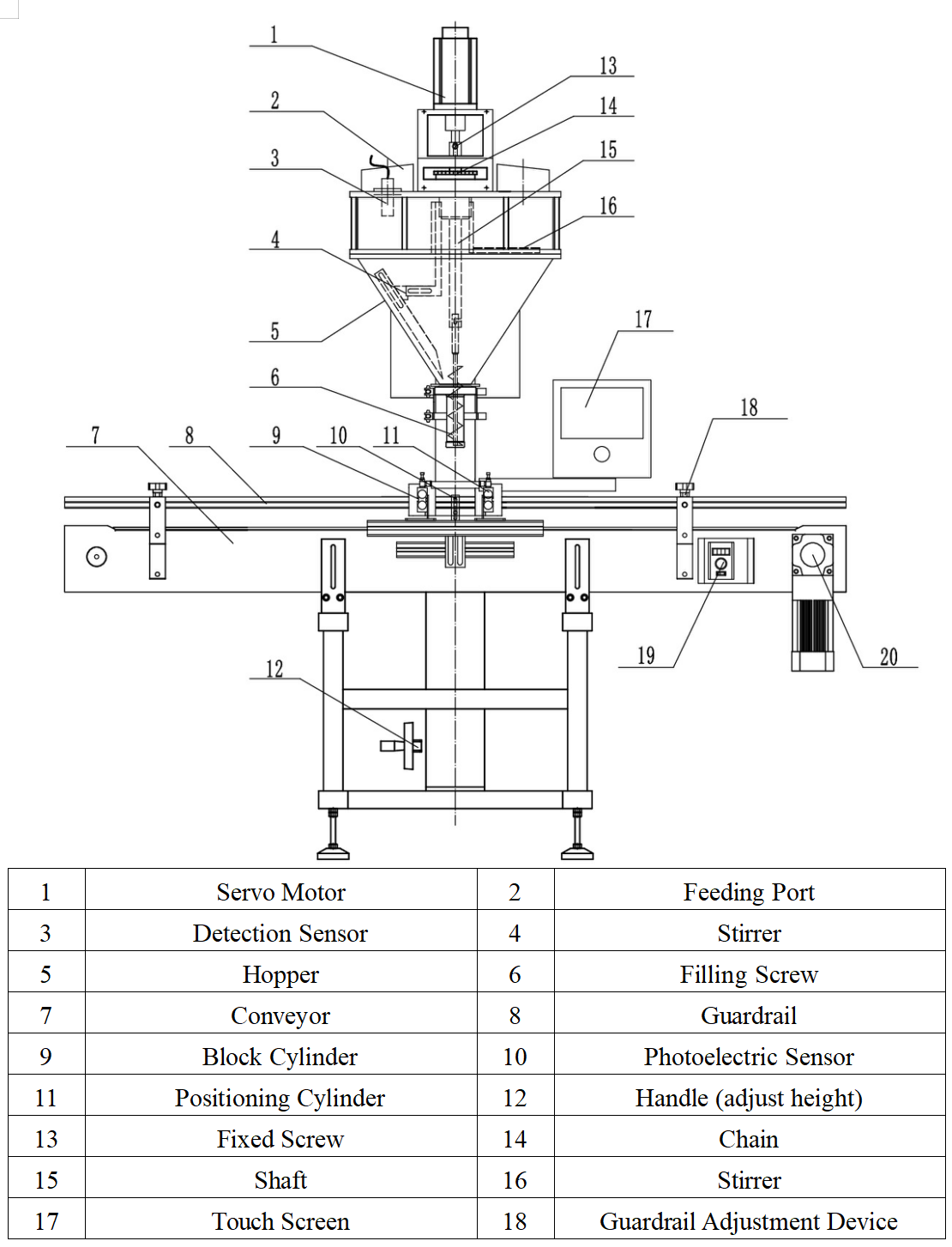

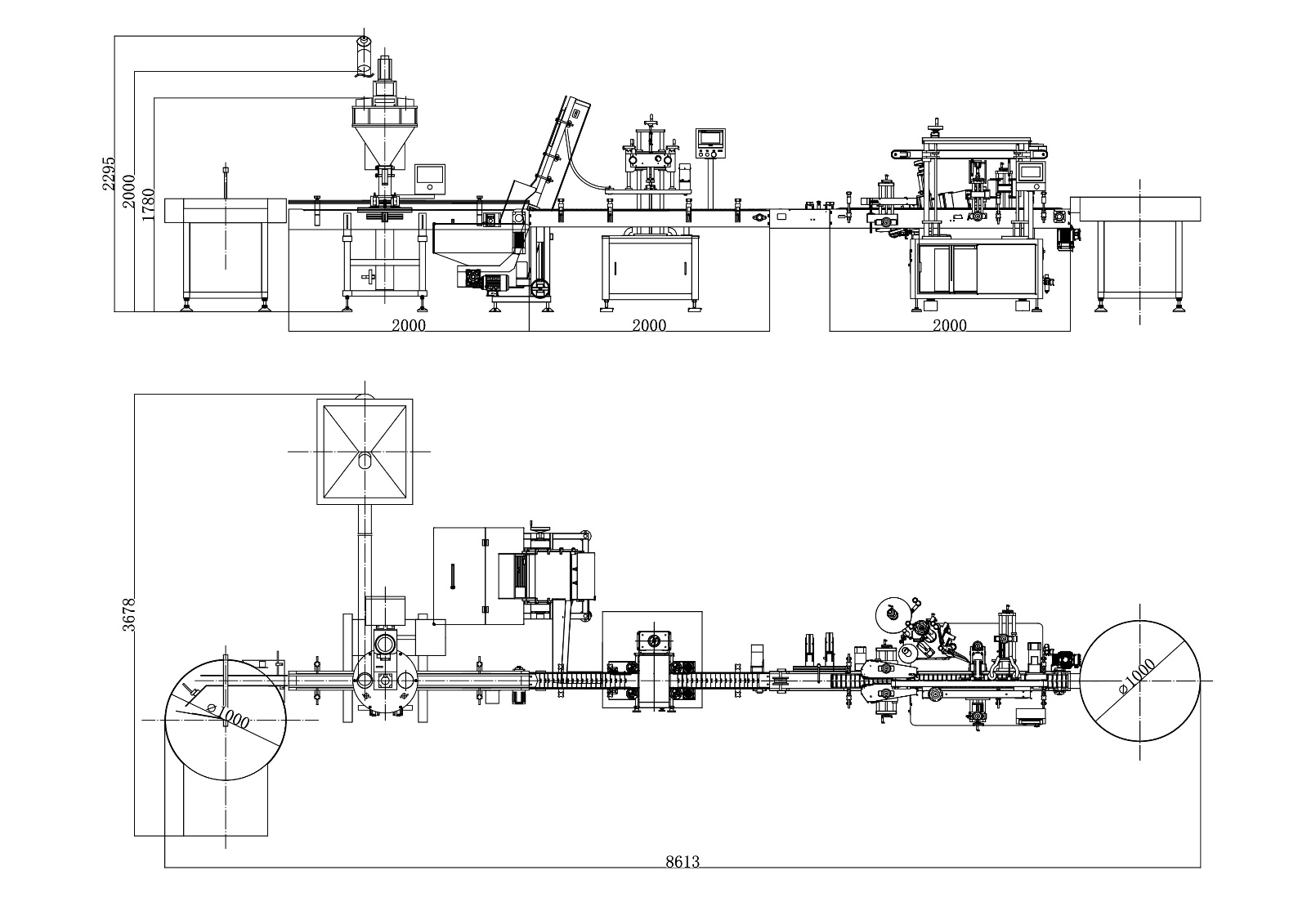

Structure Diagram

Dimension Diagram

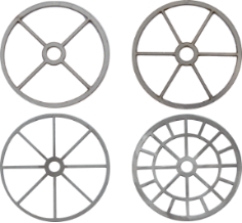

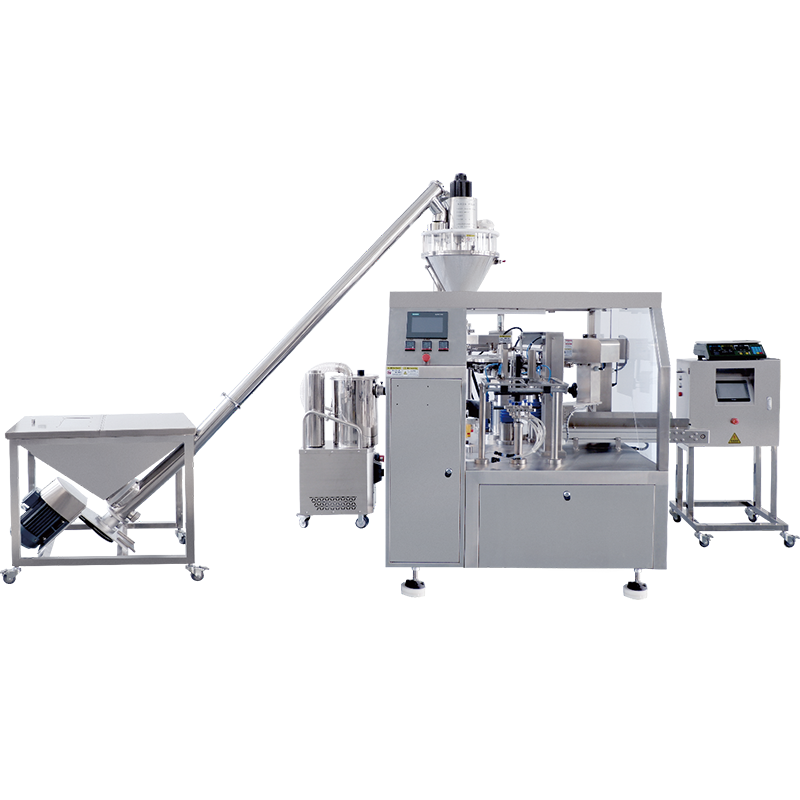

Additional Accessories

Screw Diameter (mm) | Cup Diameter (mm) | Leak-Proof Diameter (mm) | Range |

17 | 21 | / | 5g-30g |

22 | 26 | / | 20g-50g |

28 | 32 | / | 30g-100g |

34 | 39 | 41 | 50g-200g |

38 | 43 | 45 | 100g-300g |

45 | 50 | 52 | 200g-500g |

50 | 55 | 57 | 300g-1kg |

55 | 60 | 62 | 500g-2kg |

|

|

Leakage Prevention Device | Pressure Plate |

|

|

Dust Collecting Cover | Centrifugal Leakage Prevention |