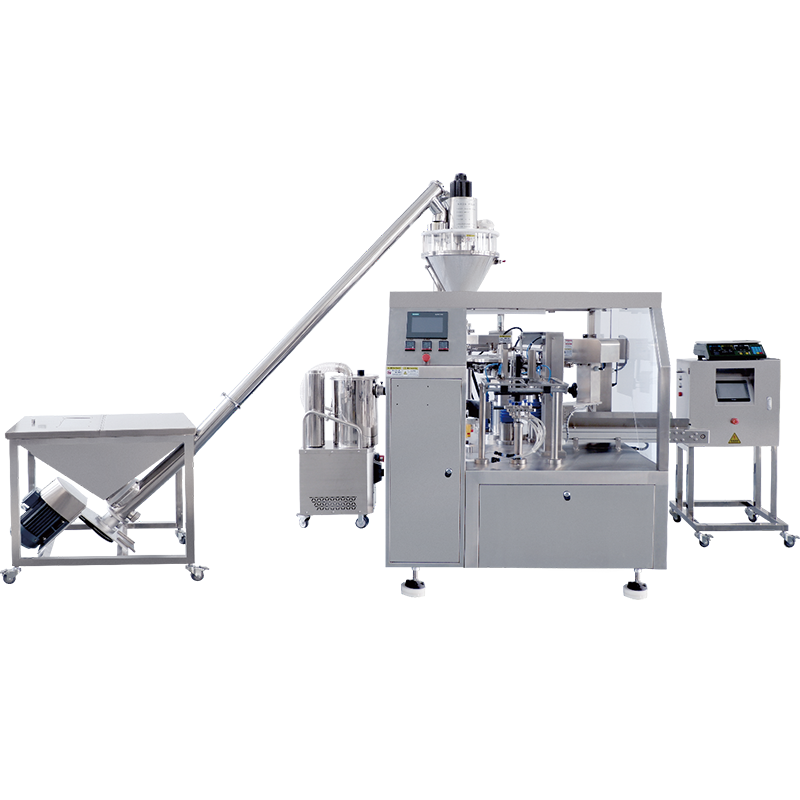

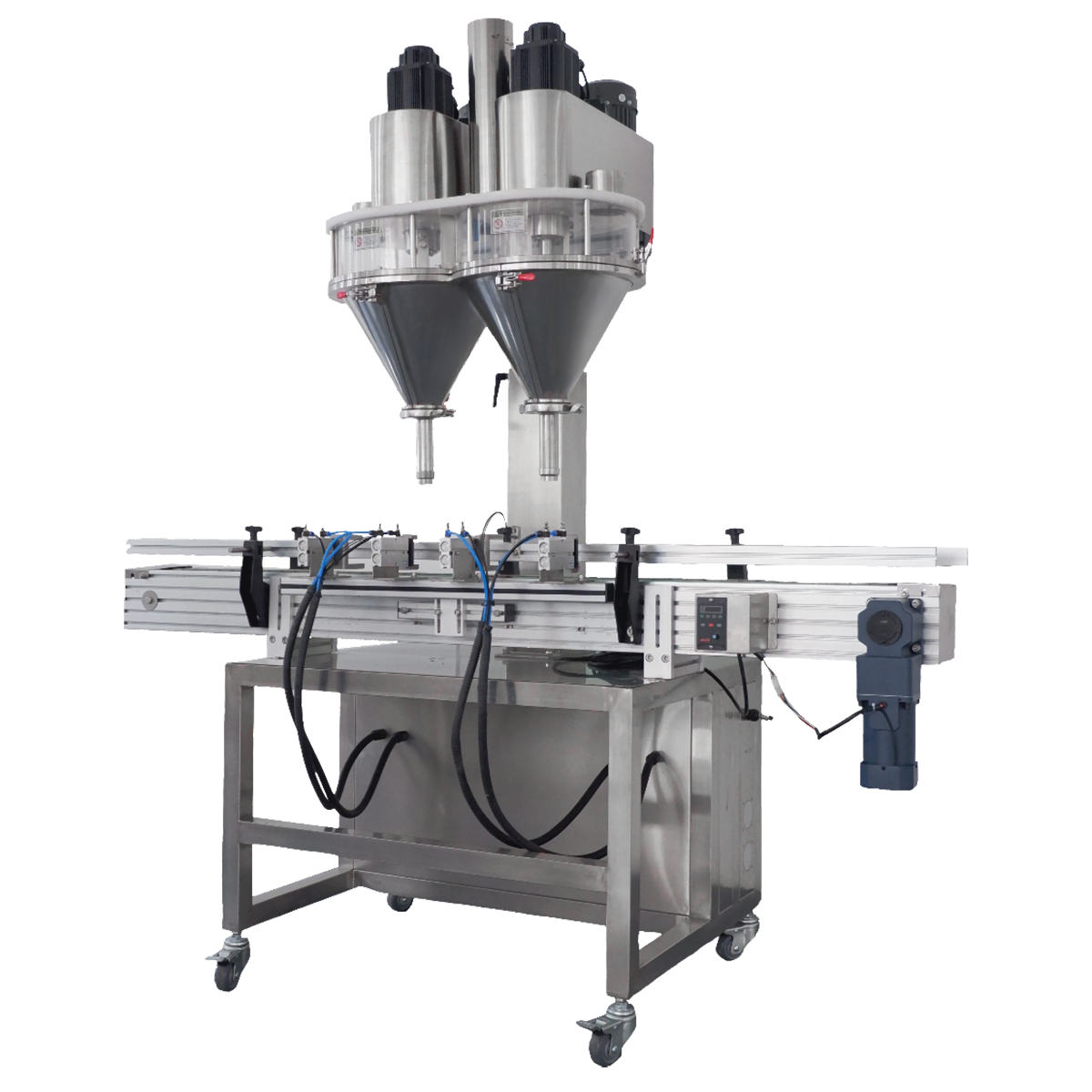

Packing Line Diagram

|

|

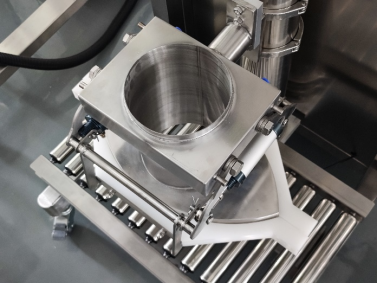

Hopper can be opened to be cleaned | Tightly clamping |

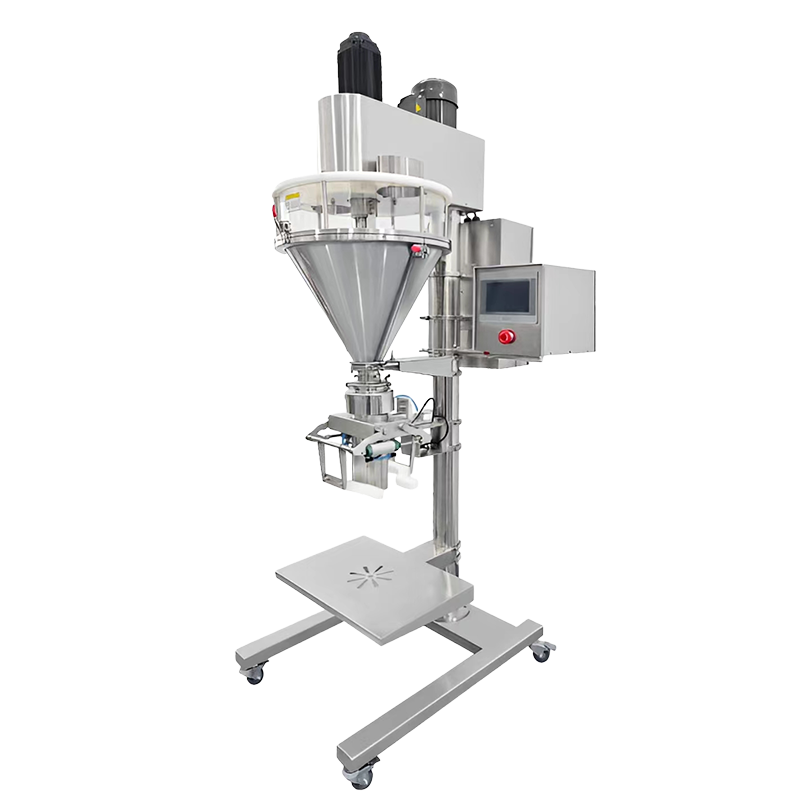

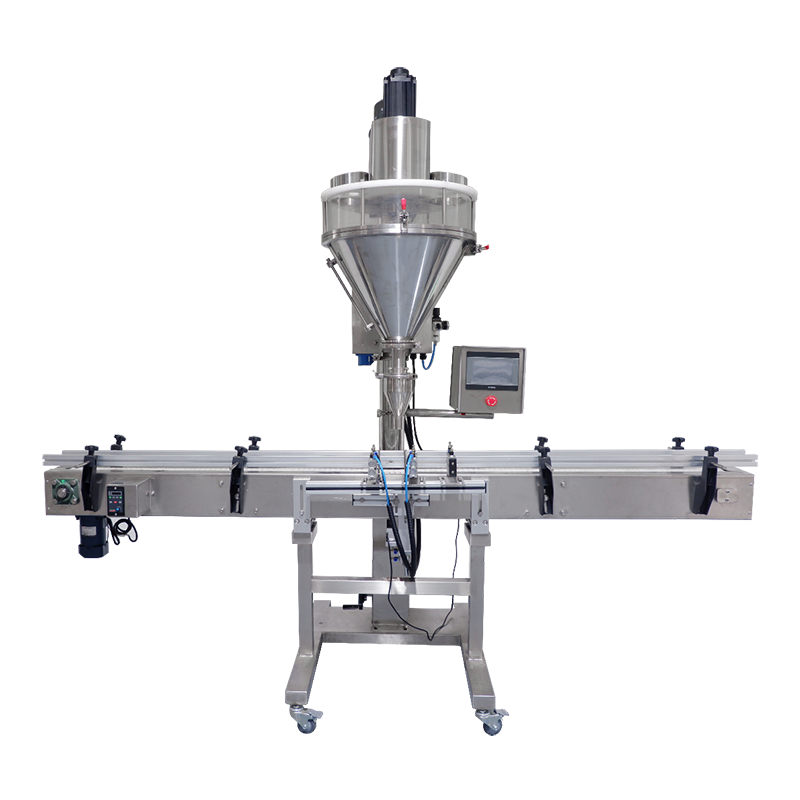

GMB-15kg Powder Packing Machine (Weighing)

Technical Parameters

Packing Weight | 5-15kg (Depends on Materials) |

Packing Speed | 120-300bags/h (Depends on Materials) |

Packing Accuracy | ≤0.3% (Depends on Materials) |

Voltage | AC380V |

Power | 1.5kw |

Air Pressure | 0.4-0.8mpa |

Hopper Volume | 70L |

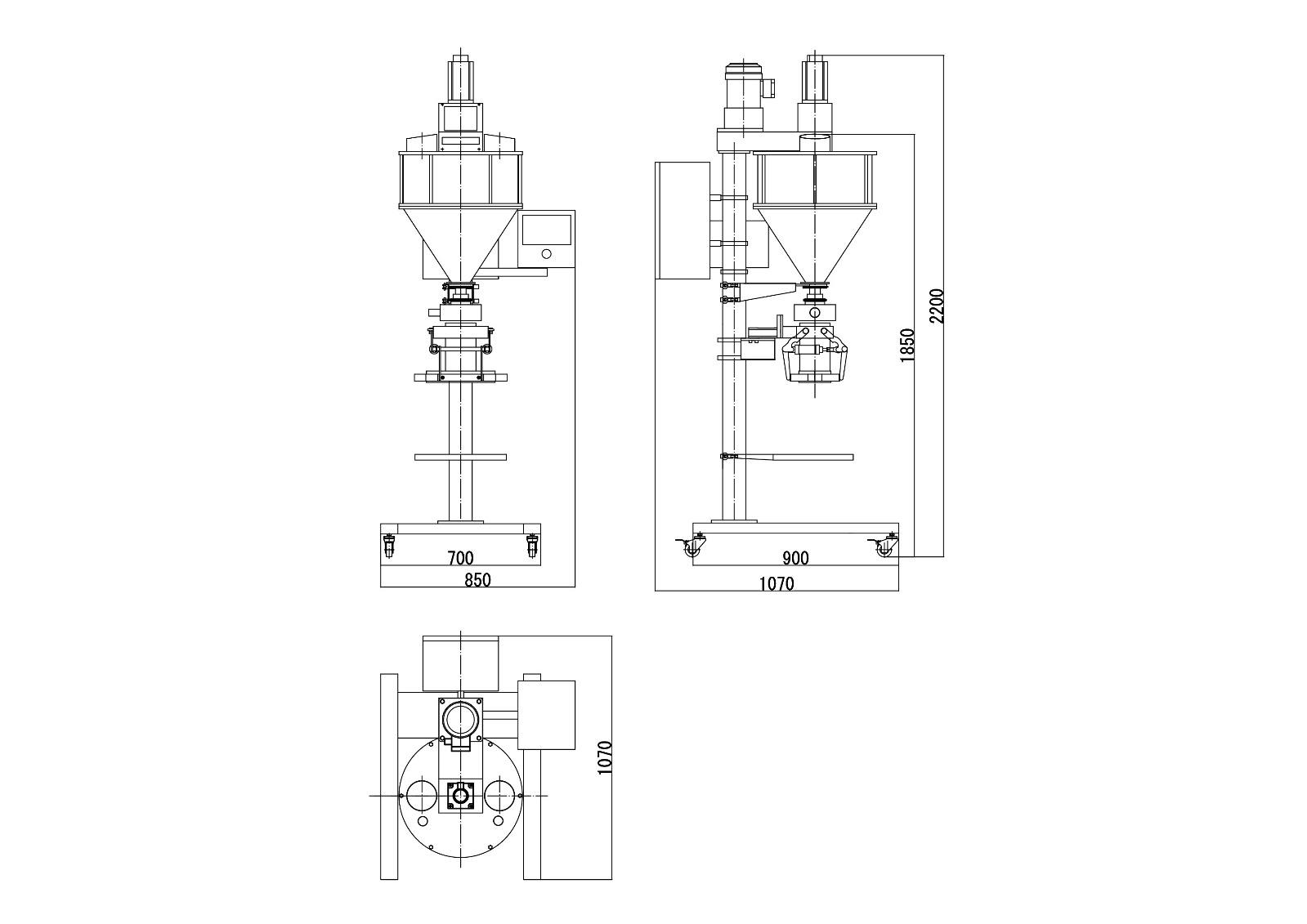

Feeding Height | 1850mm |

Dimension | 850×1070×2200mm |

(These are standard above, all parameters can be customized)

Detailed Introduction

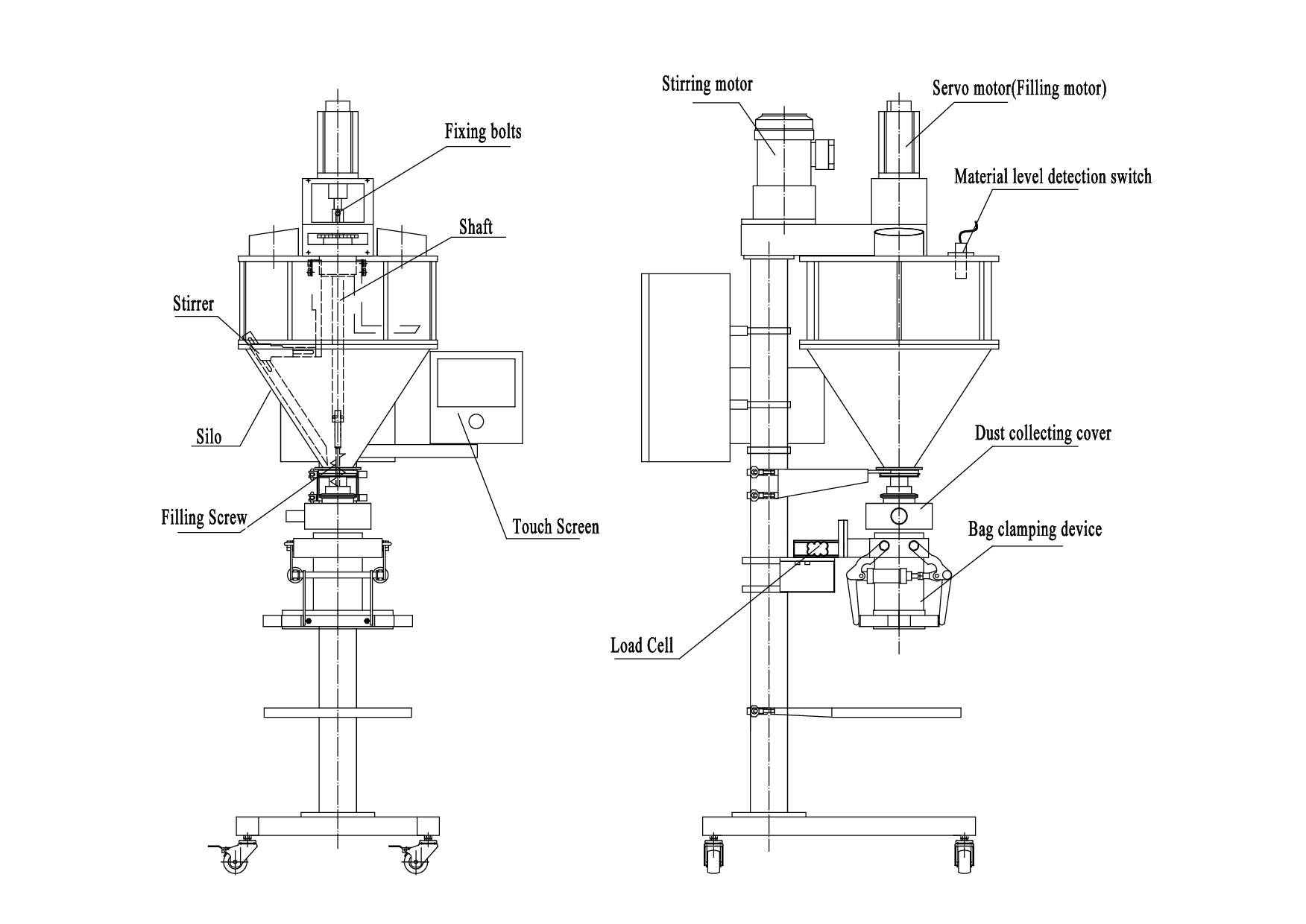

Working Principle:

Weighing measurement: Adjust the set 2 levels weight parameters of fast and slow (corresponding to the 2 level filling speed of fast and slow) to change the speed of the filling screw rotation, thereby adjusting the filling speed and accuracy:

(1) Fast filling, then start slow filling after reaching the "fast weight"

(2) Slow filling, stop filling after reaching the "slow weight"

Advantages and Characteristics

1. Accurate packaging: Adopting high quality screw and PLC control system, weighing is stable and accurate.

2. Easy to clean: The hopper can be fully opened, which is easy to clean.

3. Convenient installation: Full quick-release clamp connection.

4. Transparent silo: The material operation status is clear at a glance.

5. No leakage: There is a synchronous stirring function, which can solve a large part of the leakage problem of dry, loose and fine materials.

6. Stable structure: high-precision processing, perfect mechanical structure, highly concentric components (motor, long shaft, silo, screw, material cup, etc.), high machine operation efficiency, less wear, greatly reducing the failure rate of screw non-concentricity.

7. Easy maintenance and repair: The silo can be fully opened, and the internal components of the silo are clearly visible:

a) Convenient to adjust the relative position between agitator and screw.

b) Convenient to maintain and repair each component.

8. Simple operation: Equipped with an electronic touch screen, parameters can be set directly

9. Easy to move: equipped with universal wheels.

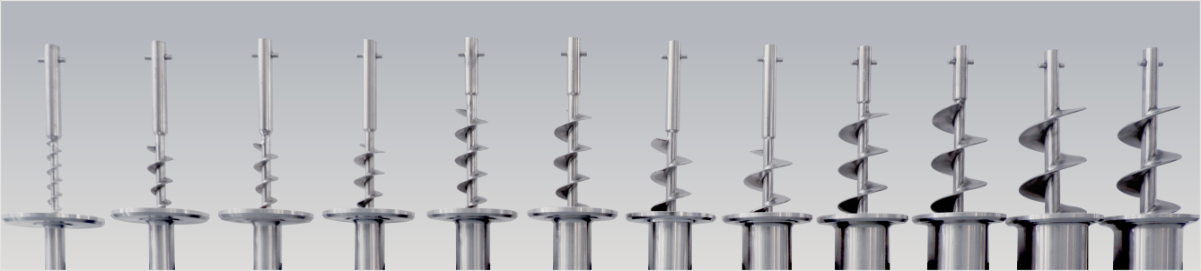

Structure Diagram

Dimension Diagram

Additional Accessories

Screw(mm) | Cup(mm) | Leakage Net(mm) | Packing Range |

45 | 50 | 52 | 200g-500g |

50 | 55 | 57 | 300g-1kg |

55 | 60 | 62 | 500g-2kg |

60 | 65 | 67 | 1kg-5kg |

64 | 69 | 71 | 3kg-5kg |

70 | 75 | 77 | 5-25kg |

|

|

Leakage Prevention Device | Pressure Plate |

|

|

Stop Valve | Cylinder Device |

|

|

Dust Collecting Cover | Centrifugal Leakage Prevention |