Auto Packing Machine (pouch)

Technical Parameters

Bag Width | 80-230mm |

Bag Length | 110-350mm |

Packing Weight | Usually 10-1000kg (depends on material) |

Packing Speed | 5-25 bags/min (depends on material and weight) |

Voltage | Single Phase 220V |

Power | 2.7kw |

Air Consumption | 0.7m3/min |

Detailed Introduction

Summary:

The three-station bag-feeding packaging machine has a small footprint, compact structure and high degree of automation. It is widely used in food, medicine, daily chemicals, chemicals, veterinary drugs (in compliance with GMP standards) and other industries.

Advantages and Characteristics

1. Replace traditional manual packaging, improve production efficiency and reduce product costs.

2. Applicable to various prefabricated bags: three-side seal, four-side seal, paper bag, self-supporting bag.

3. The parts of the machine that are in contact with materials and packaging bags are processed with materials that meet the hygiene requirements of food and medicine to ensure the hygiene and safety of food and medicine.

4. The finished packaging bag has perfect pattern, good sealing quality and high grade.

5. The electrical control system adopts advanced PLC, with friendly human-machine interface and easy operation.

6. The machine is equipped with automatic detection device as standard, which can detect air pressure, temperature controller failure, machine bagging situation, whether the bag mouth is opened, and whether the machine status can be judged.

7. The mechanical structure of this machine is compact, the transmission system is reasonably arranged, and maintenance is convenient.

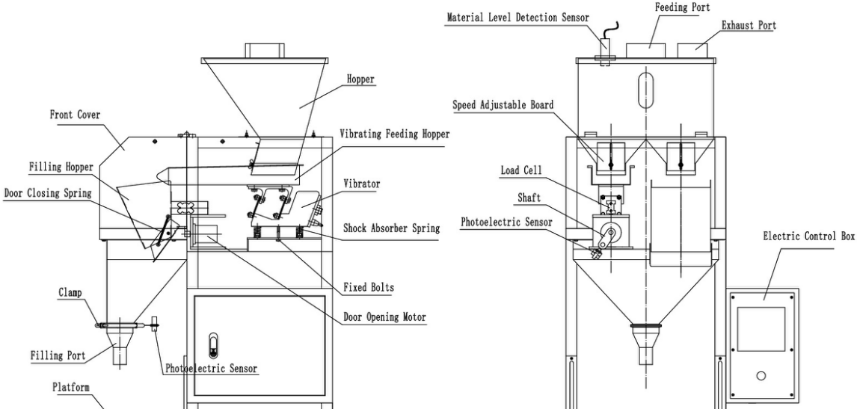

Structure Diagram

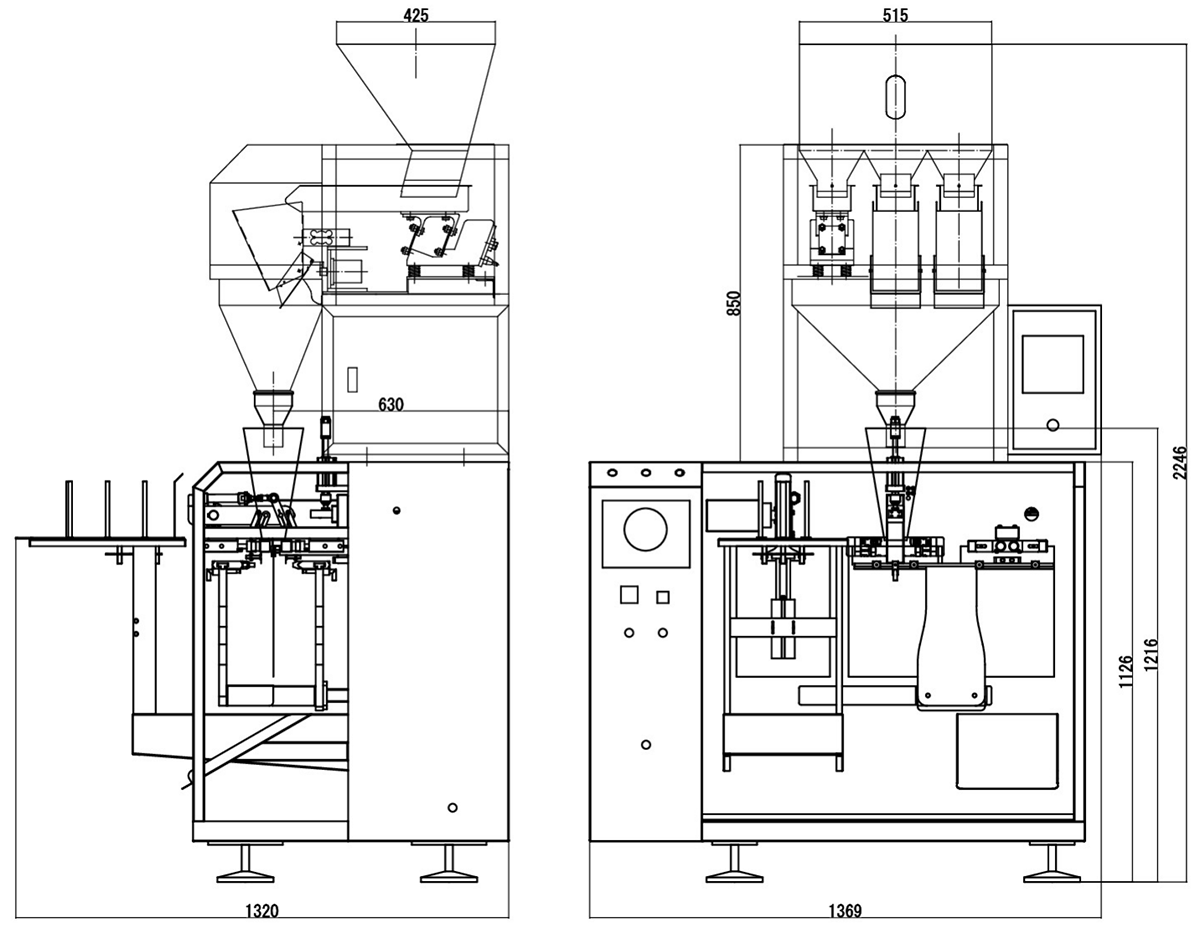

Dimension Diagram

Additional Accessories

Granule Weigher (3 weighing hoppers)

Features:

1. Stability: Adopting industrial-grade weighing module and PLC control system, weighing is stable and accurate.

2. Fast speed: Trible vibration and weighing buckets measure and discharge alternately.

3. High accuracy: Step-type multi-speed feeding, small error.

4. Auto Calculation: The system can automatically calculate the fast and slow weight, and correct the error value.

5. Stable structure: One weighing bucket corresponds to one vibrator and one weighing sensor, which are independent of each other.

6. Simple operation: Equipped with electronic touch screen, weight parameters can be directly input.

7. Easy to clean: The surrounding open design, the dust cover can be opened, and the interior is easy to clean.

Working Principle:(Weighing Measurement)

0-480g: Fast Filling(Weighing) Material enters into vibration feeder. Vibration starts fast filling until reaching the "fast weight" |

480-500g: Slow Filling(Weighing) Vibration starts slow filling until reaching the "slow weight" |

“480g” “500g” is just an example,the specific setting depends on the situation. |

Parameters:

Packing Weight | 2g-2KG (Depends on Material) |

Hopper Volume | 3.5L |

Packing Accuracy | ≤±0.3% (Depends on Material) |

Power | AC220V |

Power | 1KW |

Structure Drawing: